- Products

- Catalogs

- News & Trends

- Exhibitions

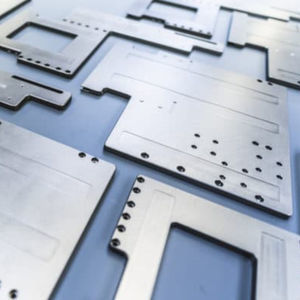

Aluminum anodizing OX-AindustrialMIL-A-8625 Type II

Add to favorites

Compare this product

Characteristics

- Type of substrate

- aluminum

- Applications

- industrial

- Certifications

- MIL-A-8625 Type II

Description

OX-A is a clear aluminium anodizing treatment in compliance with MIL-A-8625 Type II, and ISO 7599.

OX-A anodizing treatment is composed of an electrolytic aluminium oxidation process. It is performed by dipping the substrate in a sulphuric acid solution at 20°C and by applying direct electric current.

During the process, the surface of the aluminium part is transformed, creating a protective film of aluminium oxide with a typical thickness of 10-20µm.

The OX-A treatment protects treated parts against corrosion and wear. The corrosion resistance of parts anodized with OX-A passes 336 hours in salt spray in compliance with MIL-A-8625.

The treatment is used to protect automatic machinery components, in the medical field, home appliances, and industrial components.

FEATURES

CORROSION RESISTANCE

The OX-A film protects the base material from corrosion, exceeding 336 hours of salt spray exposure in compliance with the requirements of MIL-A-8625.

RESISTANCE TO LIGHT WEAR AND SCRATCHES

The layer of aluminium oxide formed by the OX-A treatment makes it possible to achieve high scratch resistance and resistance to minor wear phenomena.

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- Nickel plating

- Anodic oxidation with coloring

- Electroless nickel plating

- ISO 9001 nickel plating

- ISO 9001 anodic oxidation

- Hard anodizing

- Automotive anodic oxidation

- Medical anodizing

- High phosphorus nickel plating

- Titanium anodizing

- Industrial anodizing

- Steel nickel plating

- Aluminum nickel plating

- Stainless steel nickel plating

- Copper nickel plating

- Sulfuric anodic oxidation

- Brass nickel plating

- Bronze nickel plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.