- Production Machines

- Plastics Processing

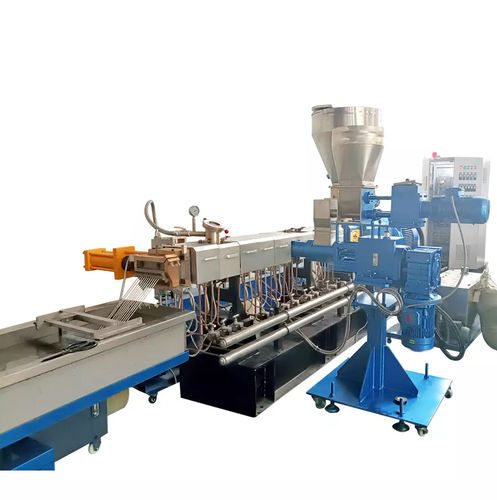

- Pelletizing extruder

- Nanjing Haisi Extrusion Equipment Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

Pelletizing extruder TSE-50Bfor PPfor PEfor ABS

Add to favorites

Compare this product

Characteristics

- Applications

- pelletizing

- Treated material

- for PP, for PE, for ABS, for PET, for PC, for PMMA, for PA, for PA66

- Number of screws

- twin-screw

- Other characteristics

- with underwater pelletizing

- Output

Min.: 135 kg/h

(297.6241 lb/h)Max.: 270 kg/h

(595.2481 lb/h)- Screw diameter

51 mm

(2 in)- Maximum speed

500 rpm

(3,142 rad.min-1)- Torque

430 Nm

(317 ft.lb)

Description

PP/PE/PA + Glass fiber plastic reinforcement extruder with side feeder.

TSE-50 Model twin screw extruder with 200kg/h.

Water cooling strand pelletizing line

The screw elements and kneading blocks are designed by preciseprocessed, agile combination, with interchangeability, which can fufil efficient sel-cleaning, transmission, compoudning, presure-forming, etc. The screw is made of high tool steel 38 CrMoALA or W6Mo5C4V3 by special heat-treatment, which is prossessed with high corrosion-resistant and high functions.

Engineer plastic generally means SAN, ABS, PET, PBT, POM, PMMA, PA6, PA66, PC and all reinforced and modified polymers used in injection and extrusion applications.

Applications:automotive, electrical, blow moulding, film and pipe extrusion, fiber, etc.

Processing methods: short fiber reinforce compounding and long-fiber thermoplastic (LFT).

Other Nanjing Haisi Extrusion Equipment Co., Ltd. products

Reinforce Modification Extruder

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Plastic sheet extrusion line

- Twin-screw screw extruder

- PVC extrusion line

- Polypropylen extrusion line

- Plastic pelletizer

- Waste granulator

- Single-screw screw extruder

- Compact pelletizer

- Compounding screw extruder

- PP screw extruder

- PVC screw extruder

- Laboratory screw extruder

- Pelletizer for the plastics industry

- Compact screw extruder

- PE screw extruder

- ABS screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.