- Industrial machines and equipment

- Surface Treatment

- Hard anodizing

- Pioneer Metal Finishing

- Products

- Catalogs

- News & Trends

- Exhibitions

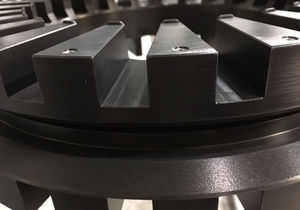

Hard anodizing Vortex aluminumautomotive

Add to favorites

Compare this product

Characteristics

- Type

- hard

- Type of substrate

- aluminum

- Applications

- automotive

Description

At Pioneer, we employ our proprietary VA-100 high-speed vortex anodizing machines to perform vortex anodizing operations. The use of these machines allows us to establish hardcoat finishes with greater wear resistance in shorter periods of time compared to conventional hard anodizing methods. This process is particularly suitable for anodizing ring grooves and lands on automotive pistons and small areas of components in high volumes.

Anodizing 50-times faster than batch

Tolerances of +/-.0001 can be achieved with Pioneer’s Vortex Anodizing

Ideal for just-in–time Production

Very compact footprint

Low labor & operating costs

Each piston monitored for quality control

Uniform coating throughout groove

No racking – quick change fixtures

Low Ra capabilities

Over 140 Million pistons have been processed in North America with VA-100 machine solutions

Related Searches

- Anodic oxidation

- Aluminum anodic oxidation

- Nickel plating

- Anodic oxidation with coloring

- Electroless nickel plating

- Small series anodic oxidation

- Large series anodic oxidation

- Passivation

- Medium series anodizing

- Hard anodizing

- Shot blasting

- Zinc-plating

- Sand blasting

- Aeronautic anodic oxidation

- Automotive anodic oxidation

- Ferrous metals shot blasting

- Medical anodizing

- Steel passivation

- Steel nickel plating

- Aluminum nickel plating

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.