- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

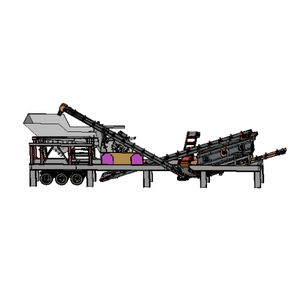

Impact crusher PTC-1 seriesstationaryfinetertiary

Add to favorites

Compare this product

Characteristics

- Technology

- impact

- Mobility

- stationary

- Other characteristics

- fine, tertiary, stone, limostone

- Capacity

Max.: 350 t/h

(214.3 lb/s)Min.: 80 t/h

(49 lb/s)- Motor power

Max.: 500 kW

(679.81 hp)Min.: 160 kW

(217.54 hp)- Opening height

1,100 mm, 1,300 mm, 1,400 mm

(43.3 in, 51.2 in, 55.1 in)- Opening lenght

Max.: 1,800 mm

(70.9 in)Min.: 500 mm

(19.7 in)- Weight

Max.: 33,000 kg

(72,752.55 lb)Min.: 10,000 kg

(22,046.23 lb)

Description

Experience the pinnacle of versatile crushing with Polygonmach Machinery’s Tertiary Impact Crusher (HSI). Engineered to deliver exceptional performance in a wide range of applications, this advanced crusher takes your aggregate production to new heights.

The Tertiary Impact Crusher (HSI) is specifically designed for fine crushing and shaping of hard and medium-hard materials. It stands as the ultimate solution for producing high-quality aggregates with precise particle shape and consistent gradation.

The Tertiary Impact Crusher (HSI) utilizes a high-speed rotating rotor that generates a powerful impact force. This force efficiently reduces the material size, resulting in finely crushed particles ideal for a variety of applications.

When it comes to stone types, the Tertiary Impact Crusher (HSI) proves its versatility. It can effectively handle various types of stones, including limestone, granite, basalt, and more. The crusher's robust design and specialized components ensure optimal performance, regardless of the stone type, making it suitable for a wide range of aggregate production needs.

Let's delve into the key components of the Tertiary Impact Crusher:

Rotor: The high-speed rotor delivers powerful impacts to the incoming material, ensuring efficient reduction and shaping.

Blow Bars: Robust blow bars withstand high impact forces and ensure efficient crushing of the stones.

Adjustable Curtains: The adjustable curtains regulate the product size by controlling the gap between the rotor and curtains, allowing precise customization.

Feed Hopper: The feed hopper efficiently directs the material into the crushing chamber, ensuring a steady and continuous flow.

Catalogs

No catalogs are available for this product.

See all of Polygonmach‘s catalogsRelated Searches

- Crushing plant

- Screening unit

- Bulk material screening unit

- Stationary crushing and screening plant

- Mobile crushing and screening plant

- Impact crushing and screening plant

- Jaw crushing and screening plant

- Vibrating sieving machine

- High-capacity crushing plant

- Primary crushing and screening plant

- Secondary crushing and screening plant

- Mobile screening unit

- Compact crushing and screening plant

- Cone crushing and screening plant

- Fine crushing and screening plant

- Stone crushing and screening plant

- Tertiary crushing and screening plant

- Construction screening unit

- Process screening machine

- Inclined screening unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.