RESOLTECH HTG-240 / HTG-245 resin is very high TG resin system specially formulated for the manufacture of tooling and large structural composites parts requiring TG’s and service temperature up to 220 °C.

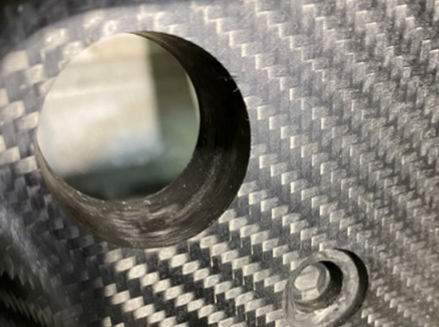

Due to its low viscosity, high wetting properties and excellent air release, it is suitable for the manufacture of structures and composite parts by infusion, injection moulding. HTG-240 / HTG-245 system contains no CMR components or VOC to reduce user exposure.

The stable low viscosity vs temperature makes of the HTG-240 a prime choice for infusion process. However, this system is not recommended for wet lay up or filament winding because the hardener HTG-245 is sensitive to moisture. For these applications, HTGL-210 / HTGL-216 is recommended.

This system gives high inter-laminar properties thanks to its exceptional wetting properties even on aramid reinforcements.

Laminates can be released from the moulds after a low temperature cure cycle (8h @ 40 °C) enabling to use of low TG plug material. Final thermo-mechanical properties will be obtained after a post curing cycle defined according later in this technical data sheet.

TG >220 °C

Low viscosity and excellent wetting properties

High thermomechanical performances

TG (°C)

220

Mix density

1.12

Mix viscosity (mPa.s)

480

Gel time on 70 mL, 4cm at 23°C

12h30m