- Production Machines

- Other Manufacturing Equipment

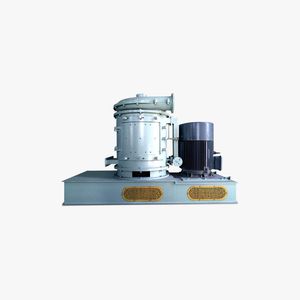

- Spiral jet mill

- Shandong ALPA Powder Technology Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Spiral jet mill MQP seriesfoodfor rubbermica

Add to favorites

Compare this product

Characteristics

- Technology

- spiral jet

- Product applications

- food, for rubber, mica, graphite, silica, quartz, silicon, kaolin, sulfur, talc, potassium manganate

- Other characteristics

- laboratory, high-speed, tangential

- Sector

- for the pharmaceutical industry, for recycling, for the plastics industry, for the chemical industry

- Final grain size

Min.: 5 µm

Max.: 150 µm

- Output

Min.: 0 kg/h

(0 lb/h)Max.: 6,000 kg/h

(13,228 lb/h)

Description

On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

The jet mill is suitable for dry grinding of various materials with Moh’s hardness below 9, especially for the materials with high hardness, high purity and high added value.

Constant temperature or low temperature, medium-free grinding,especially suitable for materials of heat sensitive, low melting point, sugary, volatile nature.

Available product size D50: 2~100μm.

No rotating parts, easy to disassemble and clean.

The whole steel plate of the main body is processed by CNC without welding seam.

On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

Working Principle

Compressed gas is used to pass the feeder ejector to bring the ground raw materials into the grinding chamber, and driven by the high-speed airflow from multiple nozzles, it is sprayed on the grinding wall in a tangential manner to achieve the effect of friction grinding. By adjusting the longitudinal depth of the grinding chamber, adjusting the grinding pressure or feeding speed, the fineness of grinding can be controlled. Compared with the fluidized bed jet mill, the controllability of the pulverization fineness is less.

VIDEO

Catalogs

ALPA Spiral jet mill MQP series

10 Pages

Other Shandong ALPA Powder Technology Co., Ltd. products

Dry Grinding

Related Searches

- Grinding mill

- Horizontal grinding mill

- Vertical grinding mill

- Food lump breaker

- Rotor lump breaker

- Impact grinding mill

- Roller grinding mill

- Waste lump breaker

- Plastic pulverizer

- Mill for the pharmaceutical industry

- Mineral mill

- Hammer grinding mill

- Laboratory grinding mill

- Compact grinding mill

- Grinding mill for the food industry

- Recycling grinding mill

- Stainless steel grinding mill

- Powder grinding mill

- Rotary drum grinding mill

- Dry milling grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.