- Industrial machines and equipment

- Surface Treatment Equipment

- PVD deposition machine

- Shanghai Royal Technology Inc.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

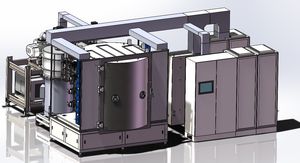

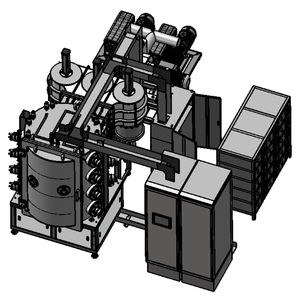

PVD deposition machine RTAC-1615sputteringarc evaporationmetalized film

Add to favorites

Compare this product

Characteristics

- Method

- PVD

- Technology

- sputtering, arc evaporation

- Deposition type

- metalized film

- Other characteristics

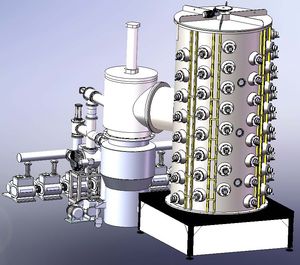

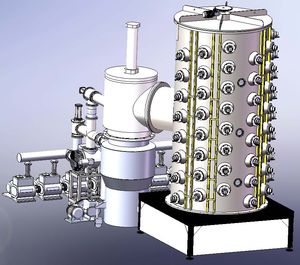

- vacuum, with rotating cathodes

- Applications

- for glass coatings, for household appliances

Description

Faucets as important consumption of our daily life, consumers and manufactures are more focusing on the creative design & surface treatment process. PVD vacuum Ion Plating is used to replace the traditional chemical electro-plating is more recommended due to its low production cost, 100% environment friendly, flexible operation features.

PVD vacuum coatings properties

Exceptional aesthetic finish

Uniform coating thickness

Superior resistance to wear and corrosion

PVD coating has a high level of hardness

Brass Faucets PVD Coating Machine Advantages:

1. High ionization rate, high through put,

2. Large capacity to satisfy mass production,

3. Excellent film adhesion and various colors are available.

4. Coating Material: Chrome, Titanium, Zr , TiAl, etc.

The multi arc + MF sputtering deposition coater RTAC1615(RTAC1618)is exclusively designed for brass faucets industries, it can coat the whole set of faucets, plumbing, valves etc.

The high lights of this machine are:

1. Equipped with cryo-pump (Polycold) device, which

Is available for plastic parts, like ABS, PC, ABS + PC, PP materials plating.

2. MF sputtering cathodes and DC Sputtering Cathodes for option.

Catalogs

No catalogs are available for this product.

See all of Shanghai Royal Technology Inc.‘s catalogsOther Shanghai Royal Technology Inc. products

Cathodic Arc Deposition Equipment

Related Searches

- Coating machine

- Vacuum deposition machine

- PVD deposition machine

- Thin-film deposition machine

- Metalized film deposition machine

- Arc evaporation deposition machine

- Thermal evaporation deposition machine

- Deposition machine for the microelectronics industry

- Automotive deposition machine

- Glass coating deposition machine

- Sputtering coating machine

- CVD deposition machine

- Short-cycle deposition machine

- Ion beam-assisted deposition machine

- Online deposition machine

- Deposition machine for photovoltaic applications

- Medical deposition machine

- Deposition machine with rotating cathodes

- Laboratory coating machine

- Optoelectronic deposition machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.