- Materials - Tools - Components

- Hand Tool, Power Tool

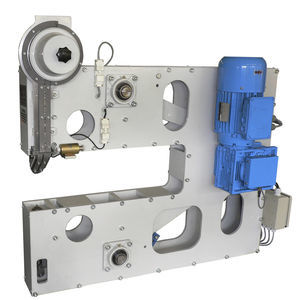

- Electric eyeleting machine

- Walter Winter Verbindungstechnik GmbH & Co.KG

Electric eyeleting machine 035_02-2automaticdoubleautomatic feed

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Operational mode

- automatic

- Type

- double, automatic feed

Description

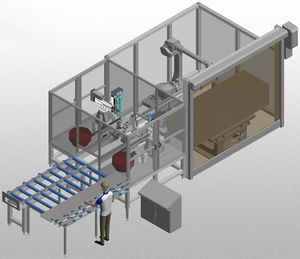

Electric double eyeletting machine for stainless steel eyelets (V2a) in extra heavy design with fixed hole spacing and with hydraulic re-pressing unit for automatic insertion of eyelets into pre-punched material. The eyelets are automatically fed and pressed in via one driven sorting drum each on the left and right. Both eyelets are inserted at the same time. The pressure of the eyelets is adjusted via an adjusting screw on the lower tool. Electronic eyelet sensing for level control in the feed rail as well as monitoring of the sorting drums. With protective housing, electrical limit switch and piece counter.

Technical data:

Control cabinet with PLC-control and operating panel

Component monitoring for already loaded workpieces

Sorting drum drive: Electrically with minimum and maximum control

Performance: 60 cycles/minute

Drive: Geared brake motor

Sorting drive: Small gear motor

Working height: Approx. 1200 mm

Weight: Approx. 1000 kg

Space required: 1300 x 2000 x 2100 mm

Air pressure: Approx. 6 bar

Projection: 200 mm freely projecting

Hole spacing: Fixed

Repressing unit: Hydraulic with aggregate

Application examples:

Automotive industry, automotive supplier, automotive, mold making, plastics processing

VIDEO

Other Walter Winter Verbindungstechnik GmbH & Co.KG products

Special machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.