- Hydraulics - Pneumatics >

- Compressor >

- Turbo-compressor >

- ABB Turbocharging

ABB Turbocharging turbo-compressors

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Engine power: 8 kW

... solution with an electrically driven turbo compressor and matching converter from a single source through one single point of contact. Highly compact, ultra-high-speed, electrically driven radial turbo ...

Celeroton AG

Engine power: 2,000 W

... of the turbo compressor series CT-NG, Celeroton is further extending its product portfolio of ultra-high-speed, gas bearing turbo compressors with a turbo ...

Celeroton AG

Engine power: 700 kW

Highly compact, high-speed, electrically driven radial turbo compressor with gas bearing for the circulation and compression of various gases and refrigerants. - High-speed gas bearings for oil free ...

Celeroton AG

Airflow: 25 m³/min - 326 m³/min

Pressure: 4 bar - 11 bar

Engine power: 200 kW - 2,000 kW

... powerful units deliver a volume flow of 25 - 330 m³/min at a pressure of up to 10 bar(g). The field of application of the turbo compressor series DYNAMIC is manifold and is mainly in the large-scale industry ...

... stage turbo-compressors. Modular single stage units providing flows up to 35m3/s and pressures up to 3 bar. For special applications, engineered single-stage turbo- compressors ...

The HV-TURBO GC compressor is a part of making the aeration 99.5% self-sustainable delivering the lowest CO2 footprint over a lifetime of a compressor – we are still working on the last ...

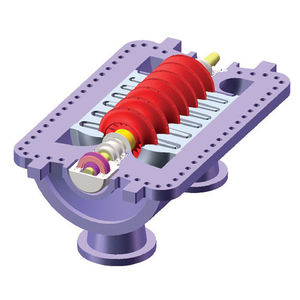

... component lifetime Disassembly of cartridge from compressor (cold) side Reduced service events and delayed OPEX Data-enabled services Simple and instant visual of turbocharger and ...

Accelleron

Airflow: 320,000 m³/h - 650,000 m³/h

Pressure: 0 bar - 7 bar

Engine power: 60,000 ch

... easier site construction Robust main air compressor unit High flow levels and superior efficiency are hallmarks of the RT’s three-stage radial single shaft main compressor design. The sturdy main ...

Atlas Copco Compressors

... 8000Km). ◘ Disassemble the pipeline from the air filter to the inlet of the turbocharger compressor casing, and rotate the turbocharger compressor impeller. The turbocharger ...

High-efficiency Compressors: Hangyang compressors have more than 40 years of design and manufacturing history. There are a series of products for oxygen compressors, nitrogen compressors, ...

Airflow: 600,000, 550,000 m³/h

Pressure: 250 bar

Engine power: 60,000 kW

Integrally geared compressors For the highest efficiency, our multi-shaft integrally geared compressors feature individually selectable impeller speed, optimized pinion speed and different compressor ...

MAN Energy Solutions

The name Compander describes a multi-shaft turbomachine, incorporating both compressor and expander stages. The energy generated during the expansion process is returned to the system to improve efficiency. Cryostar ...

Gearless, 100% Oil Free and Pure Air Turbo Compressor The compressor as the first industrial machine for which the oil is not required! Clean air without defect, low maintenance cost ...

Airflow: 3,000 m³/h - 200,000 m³/h

Pressure: 0 bar - 50 bar

The SF series is a range of single-stage centrifugal turbo compressors with an overhung, semi-open impeller (3D design), supported by a separate bearing pedestal, direct driven or provided with a separate ...

Pressure: 40 bar

TCH process compressors are horizontally split type, meaning that casing is made by two halves, jointed on a plane parallel to the rotor axis. Low and medium pressure applications (up to 40 bar) are typical for this ...

Franco Tosi

... future. Because of its highly specialized use, materials used for turbochargers must have the following characteristics: 1. Good high temperature oxidation resistance: Because turbochargers need to ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining