AMADA unloading systems

Self developed & patented double-layer auto regulating system, recyclable batts and carborundum square beams are used for the whole system continuous cycle.

Depending on the railcar type, two basic techniques of unloading are distinguished: self-unloading gravity method and unloading with FAM designed wagon tipplers. In case of the self-unloading ...

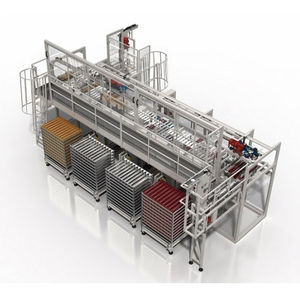

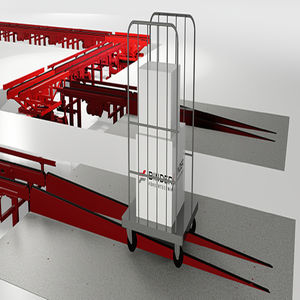

... With its Tower system. TOWER is used to make unmanned Ioading and unloading of the sheet metal for laser cutting machines. The system ensures high level of reliability, high flexibility and ...

Our best-in-class The LiftMaster Compact is the fastest and most compact loading and unloading unit in the TRUMPF portfolio. The dynamic and variable automation solution is particularly attractive for fast sheet processing ...

TRUMPF Maquinaria, S.A.

The central height of the unloading device can be adjusted electrically for easy operation. The unloading device is equipped with automatic pipe weighting system. So Customer can know ...

Rotary Discharger Bühler's rotary discharger type MZDG is employed for the discharge of free-flowing and non-free-flowing materials, primarily below batching scales. The module can also be used for volumetric feeding ...

Bühler Group

... vibrator, so that blockages due to bridging are prevented. Thanks to the discharger, the large discharge port which is otherwise essential for free discharge is reduced to a small, much more practical ...

... . Short hopper discharge units are mounted directly below the bulk hopper. Hopper discharge units are an ideal solution for customers who require a solution from silo outlet to conveyor inlet. The hopper ...

... excellent durability. Features _ Electrical pusher with adjustable force limiter _ Two point magazine clamping system _ LCD control panel _ single-color signal lamp and horn _ Anti-static conveyor ...

ASYS GROUP

... Autoflow series is composed of automatic systems for loading and unloading ends line machines. This system also stores the ends in specific metal trays in order to create inter-operational ...

CLEVERTECH

It can be carried in front of the press machine and installed/removed by using a overhead crane, forklift and hand pallet truck. 1 set of pre-roller stand is applicable for multiple press machines. It takes 45 min. to complete a die ...

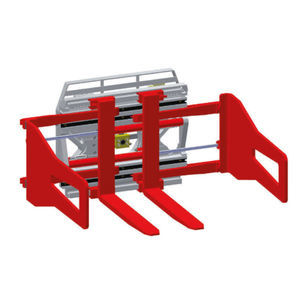

... a pressure relief valve and pressure gauge. Fork positioning is manual. The Durwen direct drive rotator uses a worm wheel system protected against the ingress of dirt and will give a long service life. The unit is not ...

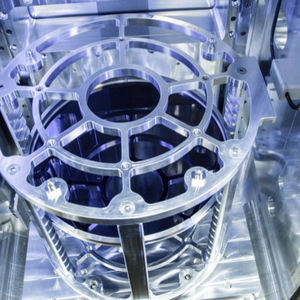

The Adenso FLP FOUP300.VAC.LoadPort enables direct loading of a FOUP in a vacuum environment. No atmospheric robot handling necessary Saves up to 80 percent clean Suitable for Lab.Applications

Automatic loading and unloading machines are machines that enable the transfer, palletization or loading of all kinds of products or semi-products in various lines. Automatic loading ...

The model ZBB 1600 big-bag discharging station for dust-free discharging of dry, powdery solids. Thanks to the telescopic frame design, varying big bag sizes can be handled on the site without a problem. All common screw conveyors with ...

There are various options for loading and unloading roller containers at floor level. With the BINDER dolly conveying, roll containers can be loaded and unloaded as follows: - manually - automated - at floor level - ...

... There is a pressure relief design, ensure that the PCB board is not pushed the bad * Automatic detection of fault code display * Easy to operate,adopt touch screen interface * SMEMA compatible

Shenzhen Ruitian Laser Co., Ltd.

Unloading of sacks and big bags on the same discharging unit Setting up of big bags on the deconditioning station via a forklift, an overhead crane and a handling cross. Mild steel, stainless steel 304 and 316 manufacturing PALAMATIC ...

Max.loading capacityo ( KG ) 50 Weight (kG) 1220 Size ( t) 1200*565*450 Axis 4/6/8

... WORKS: 1. The semitrailer with the container is hydraulically attached to the system. 2. The operator adjusts the system to all possible angle differences using the system's hydraulics. 3. ...

SmartTEH

... state-of-the-art container loading system that ensures simple, fast, and secure loading with just the push of a button. But we don’t stop there – our expertise extends to a comprehensive lineup of material-handling systems ...

... Firstly, the cost of the pallets can be saved and secondly the container can be more effectively loaded. In comparison to systems with pushers and stationary turning devices, the pallet turning device with pusher offers ...

... height for the most basic designs with a single discharge as well as the more sophisticated units with options including: dust-free discharge to minimize material waste and spillage controls ...

Your suggestions for improvement:

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining