- Detection - Measurement

- Position, Speed and Acceleration Measurements

- Linear displacement sensor

- AMETEK Factory Automation

- Products

- Catalogs

- News & Trends

- Exhibitions

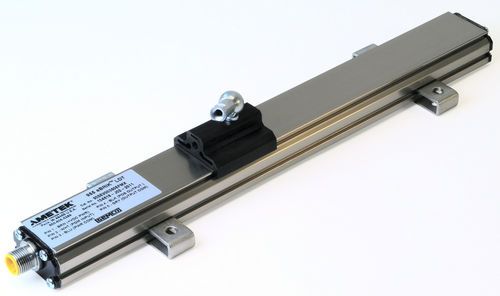

Linear displacement transducer 955 eBrik™ seriesnon-contactmagnetostrictiveanalog

Add to favorites

Compare this product

Characteristics

- Type

- linear

- Contact / non-contact

- non-contact

- Technology

- magnetostrictive

- Output signal

- analog

- Measurement object

- metal

- Other characteristics

- precision

Description

The Ametek/Gemco 955 eBrik is a non-contact linear displacement transducer. It is used in accurate positioning feedback for automated systems.

Employing a magnetorestrictive technology, the model is designed with no moving parts, thus eliminating the risk of wear and tear. It also has field programmable zero and span settings, while electronic diagnostic feedback is transmitted through the analog output. The transducer operates with an accuracy of ±0.03%. Built with a rugged aluminum enclosure with an IP67 class rating, the model can resist any shock.

The machine is applicable for use in automated or processing factory machinery. It is suitable for a variety of industry applications, such as extrusion equipment, plastic injection molding, die casting, tire and rubber, material handling, web tensioning, hydraulic/pneumatic cylinder actuation, and hydroelectric power generation.

Catalogs

No catalogs are available for this product.

See all of AMETEK Factory Automation‘s catalogsRelated Searches

- Position transducer

- Linear position transducer

- Displacement transducer

- Linear displacement transducer

- Limit switch

- Analog output position sensor

- Non-contact position transducer

- Magnetic position transducer

- Industrial position sensor

- Analog displacement transducer

- IP67 position transducer

- Metal position sensor

- Non-contact displacement transducer

- Compact position transducer

- Absolute position transducer

- Rugged position transducer

- Metal displacement transducer

- Precision displacement transducer

- Precision position sensor

- Industrial displacement transducer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.