- Products

- Catalogs

- News & Trends

- Exhibitions

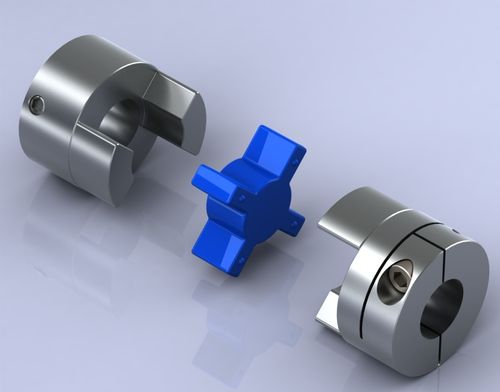

Jaw coupling SC seriesflange

Add to favorites

Compare this product

Characteristics

- Type

- jaw

- Installation system

- flange

- Torque

Max.: 78 Nm

(57.5298 ft.lb)Min.: 0.13 Nm

(0.0959 ft.lb)- Rotational speed

Max.: 8,000 rpm

(50,265.48 rad.min-1)Min.: 4,000 rpm

(25,132.74 rad.min-1)

Description

Advantages:

High torque capabilities

Different material choices for the spider allow the user to choose torsional stiffness

Somewhat “fail-safe”, in the sense that the driving hub will continue to turn the driven hub after failure of the spider

Easy installation in blind or difficult installations – all jaw couplings have through bores

Dampens variations or spikes in torque, usually caused by the driving element, protecting the support bearings and the driven component, and reducing vibration

Wear element can be reversed before being replaced, doubling life

Rugged, can function well in harsh environments

Replaceable, inexpensive wear element

Disavantages:

Relatively high reactive forces exerted on support bearings, proportional to misalignment

Even preloaded, so-called “zero backlash” jaw couplings have considerable wind-up, which is essentially the same as backlash, and disqualifies jaw couplings from servo applications

Accommodates relatively small misalignments, considering large size of couplings

Typical Applications:

Pumps, particularly gear, lobe, vane, and reciprocating pumps; also applications involving piston motors, or any system with high torque and vibration, where relative angular location of the two shafts need not remain constant. High-temp spider option good for down-hole directional drilling applications.

Catalogs

No catalogs are available for this product.

See all of OEP Couplings‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.