- Materials - Tools - Components >

- Lubrication >

- Compressor lubricant

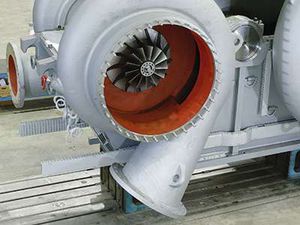

Compressor lubricants

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Viscosity: 0.000032 m²/s - 0.00015 m²/s

Pour point: -24 °C

Flash point: 284, 272, 248, 238, 244 °C

... The use of DACNIS allows real cuts in the operating costs of the compressed air production facility by optimising the compressor efficiency. Extending the service life of the separating filter elements. The DACNIS ...

TotalEnergies Lubrifiants

Viscosity: 0.000032, 0.000127 m²/s

Pour point: -33 °C

Flash point: 238 °C

The formulation of the DACNIS LD endows them with the following properties : - remarkable thermal and oxidation stability and hence a drain interval of 4000h under standard conditions of use, - reduction in the formation of carbonaceous ...

TotalEnergies Lubrifiants

Viscosity: 0.000046 m²/s - 0.00011 m²/s

Flash point: 278, 280 °C

... thermal stability of the lubricant under high temperature conditions. Low foaming tendency for turbocompressor applications. Low volatility. Low vanish and carbon deposits. Protection against rust and corrosion. Compressor ...

TotalEnergies Lubrifiants

Flash point: 260 °C

This vacuum pump oil has excellent viscosity characteristics. Its good chemical resistance, low vapor pressure as well as its better stability when pumping oxidants such as acid and alkaline vapors, makes it superior compared to standard ...

MOLYKOTE® Compressor Oils are formulated to meet , and often exceed , the OEM lubrication requirements for rotary screw vacuum pumps and compressors. They offer rust and oxidation protection; ...

Specialist lubricants for the safe and efficient operation of compressor installations Range for use in all types of air compressor, especially reciprocating and rotary screw compressors ...

CASTROL Industrial

AIRPRESS oils are multifunctional fluids based on mineral oil and ester oil. They offer good lubricating capacity and corrosion protection. AIRPRESS oils have a foam-reducing effect and accelerate air release. They disperse ...

Klüber Lubrication

Operating temperature: 220 °C

Pour point: -33 °C

Flash point: 240 °C

The Shell Corena range of air compressor oils has been developed to enable equipment operators to select the oil that will deliver optimum value to their operations through enhanced wear protection, long oil life and ...

Shell Lubricants

Operating temperature: -35 °C - 135 °C

Viscosity: 0.0001, 0.000014 m²/s

Pour point: 240 °C

... sufficient amount of lubricant with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Assess the lubrication frequency and quantity on basis of service ...

OKS Spezialschmierstoffe GmbH

Operating temperature: -40 °C - 135 °C

Viscosity: 0.000046, 0.000008 m²/s

Pour point: 240 °C

... sufficient amount of lubricant with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Assess the lubrication frequency and quantity on basis of service ...

OKS Spezialschmierstoffe GmbH

Operating temperature: -45 °C - 135 °C

Viscosity: 0.000032, 0.000006 m²/s

Pour point: 230 °C

... sufficient amount of lubricant with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Assess the lubrication frequency and quantity on basis of service ...

OKS Spezialschmierstoffe GmbH

Operating temperature: -5 °C - 90 °C

Flash point: 180 °C - 245 °C

... blockage in the desolventiser, as well as longer oil life and longer oil change periods. Protects the good condition of the compressor. Ash-free hydraulic. Available in 1, 5, 20, 50, 50, 209, 1000 litre sizes. ISO viscosity ...

Operating temperature: -43 °C - 232 °C

Pour point: -29 °C

Flash point: 220 °C

... Food Grade lubricant, rated H1 for incidental food contact and meets USDA 1998 H1 guidelines. Super Lube® Multi-Use Synthetic Oil is Kosher Certified. Available with UV additive for traceability – validates the ...

Synco Chemical Corp

... forming a stable suspension. ASO Oil Reinforcement can be added to mineral oils already in use in gearboxes, bearings and compressors to reinforce the base oil against overload, shock loading etc… ASO Oil Reinforcement ...

Operating temperature: -50 °C - 120 °C

... Trademark registered MOSH/MOAH Free FOODLUBE Hi-Power is a range of hydraulic, compressor and airline oils, designed to maximise power transfer whilst lubricating and dissipating heat to protect ...

Viscosity: 0.000018 m²/s

Pour point: -49 °C

Flash point: 226 °C

100 % synthetic oil. High-performance multigrade lubricant formulated from PAO and ESTER synthetic base oils, strong protection against wear and reduction of internal friction. Suitable for modern petrol or Diesel, natural-aspiration, ...

Operating temperature: 15, 40, 100 °C

Pour point: -15 °C

Flash point: 220, 230 °C

... oils acc. to DIN 51515-1: TDP and DIN 51515-2: TGP. For the lubrication of steam and gas turbines, generators, turbo compressors, pumps and transmissions. Furthermore used as lubricating ...

FUCHS PETROLUB SE

Operating temperature: 15, 40, 100 °C

Pour point: -60, -54, -47, -50 °C

Flash point: 240, 260, 250 °C

... air release. Allow service intervals to be extended. Lubricating oils VDL according to DIN 51506 and synthetic hydraulic oils according to DIN 51524-2/3: HLP/HVLP. Fully-synthetic screw compressor ...

FUCHS PETROLUB SE

Operating temperature: 15, 40, 100 °C

Pour point: -50 °C

Flash point: 271 °C

High performance synthetic air compressor fluid, excellent biodegradability according to OECD 301C > 60%. Excellent thermal and oxidation stability. Guarantee a reliable corrosion protection and compatibility with elastomers For ...

FUCHS PETROLUB SE

Compressor E 100 is a synthetic ISO VG 100 high performance ester-based compressor lubricant that utilises the latest available additive technology providing outstanding resistance to ...

Viscosity: 0.000046 m²/s

COMPRESSOR VRH is a semi-synthetic lubricant for air compressors, vane compressors and screw compressors. This product stands for keeping your compressors ...

Viscosity: 0.000018 m²/s

Pour point: -21 °C

Flash point: 230 °C

Lukoil Lubricants GmbH

Operating temperature: -10 °F - 300 °F

... reciprocating & rotary compressors. Solvent refined & clay filtered for long lasting, anti-foul operation. Cleans valve seat deposits & extends life. APPLICATIONS: Portable and stationary rotary screw, rotary vane ...

Operating temperature: 0 °C - 220 °C

High quality compressor oils of the type VDL DIN 51506. Produced from specially selected solvent raffinates with outstanding aging resistance and proven additives. Suited for use in all air compressors ...

Pour point: -45, -42, -39 °C

Flash point: 204, 192, 197 °C

... SHC Rarus Series – synthetic air compressor oils that can meet the demands of today’s severe service conditions. Our Mobil SHC™ Rarus Series synthetic air compressor oils protect vane and rotary screw ...

ExxonMobil Lubricants & Petrol Spec

Operating temperature: -35 °C - 120 °C

Viscosity: 0.000064 m²/s

Fully synthetic screw compressor oil of the latest generation especially for very long relubrication intervals Application Especially developed for the lubrication of screw compressors ...

Operating temperature: -40 °C - 300 °C

... APPLICATIONS Lubricates cable connectors, battery terminals, valves, compressors, taps, winches and precision mechanisms. Protects electrical and electronic systems. Lubricant for rubber and plastic ...

It is intended for lubrication of medium and high-pressure piston and rotary compressors and air blowers operated in many areas of industries and transport. It has an oxidation resistance at high temperatures ...

Optimal Oil

Pour point: -30 °C

Flash point: 172 °C

... Denison, Cessna, Hydreco and Worthington. It is also suitable for the lubrication of workshop equipment, reducing gears, bearings, compressed air systems and air screw compressors. Density at 15°C ...

Ardeca Lubricants

Operating temperature: 40 °C

... --------------------------------------------- VOLTRION electro-ionized bases are unique sustainable base oils for the lubricants & metal working industry. These naturally derived oils improve the quality of formulated ...

Pour point: -30 °C - -12 °C

Flash point: 210 °C - 246 °C

... continuously. With its superior resistance to heat, oxidation and moisture, Monolec R & O Compressor / Turbine Oil significantly outperforms ordinary commercial air compressor and turbine oils. It contains ...

Lubrication Engineers

Operating temperature: -25 °C - 250 °C

APPLICATION COMPRESSIA is a lubricant for piston, oil injection and dry rotary air compressors, centrifugal compressors and vacuum pumps (ISO68 or ISO 100). TECHNICAL PERFORMANCES Exceptional ...

MYLUBRICANTS

... low volatility and excellent lubricity. They are suitable for very demanding reciprocating air compressors, as well as rotating compressors and turbochargers where they provide superior cleanliness.

Your suggestions for improvement:

Compressor oil consists of a petroleum product base with synthetic or mineral additives. The additives are very important for improving lubricating characteristics such as viscosity, pour point and resistance to oxidation.

ApplicationsThe use of a lubricant is intimately related to the type of compressor and the chemical composition of the gas being compressed. For example, in reciprocating compressors, where temperatures can reach 200° C, the oil must withstand abrasion and leave only minimal deposits on the valves.

In contrast, rotary compressors operate at lower temperatures and the oil is used several times. Thus, it should resist oxidation. In refrigeration compressors, the oil must be compatible with the refrigerant gas, with which it is in constant contact. It must have an appropriate pour point enabling it to flow at low temperature.

Choosing the right oil can help avoid breakdowns, wear, corrosion and the clogging of filters, among other problems. It will prolong the useful life of the compressor, reduce operating costs and improve efficiency.

- Improved performance

- Less wear

- Extended working life

- Lower maintenance costs

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining