- Packing - Handling - Logistics >

- Conveying >

- Dough conveyor

Dough conveyors

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... modules: roller and axial wheels, ball planes, packing tables, frames, supports, couplings, guides adaptation, conveyor belts. All conveyors from Imbal Stock series are designed to offer a versatile ...

... bakery operations, the Belt Dough Corner stands as a linchpin for seamless dough transport. Whether your production line requires a 90-degree or 180-degree turn, this machine offers the perfect solution ...

Unmatched Precision The Dough Docker unit stands out as a pivotal solution in the bakery technology landscape. This piece of equipment excels in docking dough with unparalleled precision. making it an ...

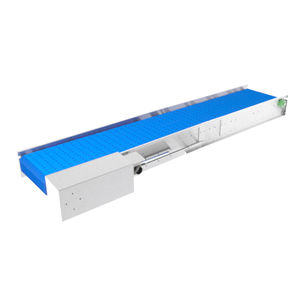

The Adjustable Height Belt Conveyor by Farhat Bakery Equipment is engineered to bring flexibility and efficiency to your bakery operations. This innovative conveyor automatically adjusts its height, ensuring ...

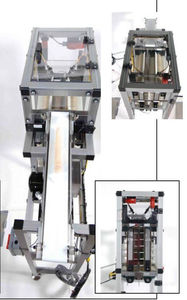

DOUGH CUP ELEVATOR - CE100 The Glimek CE100 Dough Cup Elevator for bakeries is a robust step-by-step elevator in stainless steel for transporting dough pieces from Rounder into the ...

Glimek

... Independent motor control for upper and lower parts 3. Working width: 1000mm 4. Dimensions: 6500X1930X1500 5. The conveyor belt adopts pneumatic tensioning and pneumatic deviation adjustment, ...

Bulk throughput: 500 kg/h

Effective width: 600 mm

Conveyor for molding semi-finished breadcrumbs CM-600 is intended for forming a breading layer with subsequent division into dough pieces before baking. Previously prepared dough mass ...

... transport the dough pieces from the upstream forming equipment and, secondly, to allow the dough pieces to rest. Exact specification for all dough types To prevent adhesion, Baker ...

The cutting and forming conveyor is designed for the automatic continuos process of the sponge, reducing any manual work and increasing the product output. The conveyor, mobile, is provided with all the ...

... regulated by OSHA can now be solved by the Kraken Accumulator/Feeder Transfer system, KPAFT-300. APPLICATIONS • Rolled pie dough in a wrapper • “Bag-in-box” multi pack applications

For any application. Transport from A to B or from advanced, dynamic buffer systems for product cooling in combination with linear loading or lift loading.

Peerless offers a range of Dough Conveyors to meet specific dough handling requirements between the mixer and the make-up or forming equipment. With added options, Peerless Conveyors ...

Coil conveyors are extremely versatile machines. They can be used to freeze, cool, leaven, dry or pasteurise different types of product, both before and after packaging. At a conceptual level, they are long conveyor ...

... to 2000 p/h The advantages • Ideally used with an intermediate proofer • Easy to use • Time saving in the handling of dough pieces

Maximum load: 80 kg

Speed: 1.33 m/s

Arched belt conveyors allow changing the direction of transported products on the conveyor belt. They ensure continuous, stable and even flow of products regardless of their shape. HASBORG offers a wide ...

Bulk throughput: 0.1 kg/h - 2,000 kg/h

Conveyor built in stainless AISI 304 complete of rotating cutting disc mounted on the product forwarding auger extremity. The curd blocks feed the large accumulation hopper and through the forwarding auger (with diameter ...

Comat

DESCRIPTION The Workbelt Conveyor is placed at RheonPan® Precision exit to transfer dough pieces to other machines or allow manual moulding thanks to a worktable on each side of the conveyor.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining