- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

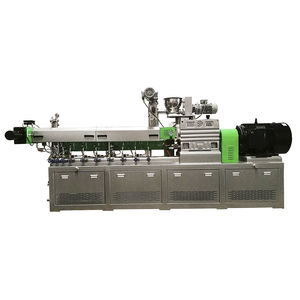

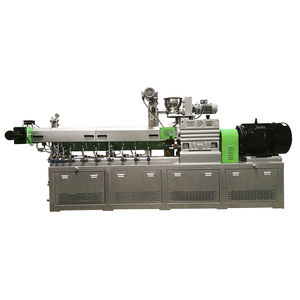

Plastics recycling extrusion line ACS-PROpelletizingcompoundingfor PET

Add to favorites

Compare this product

Characteristics

- Type

- plastics recycling, pelletizing, compounding

- Treated material

- for PET, for PP, for PVC, for PTFE, for PE-RT, for HDPE, for PE, for PVDC, for silicone rubber, for EVOH, for LDPE, for PA66, for WPC, for EPS, for TPU, for PC, for BOPP, for CPP, for polystyrene, for PMMA, for PEX, for polycarbonate, for PA, for PLA, for PP-R, for EVA, for ABS

- Other characteristics

- compact, with air cooling

- Applications

- agricultural film, for films and bags

Description

ACS-Pro Used Plastic Compounding Pelletizing Recycling Machine With Dust Removal Device

Top-of-the-range crushing compacting pelletizing machine, excellent degassing and filtering performance for recycling

The ACS-Pro is the entirely new standard recycling and pelletizing system with optimized super long L/D ratio, filtering ahead of vacuum degassing, specially suit to the waste plastics such as high contaminated and heavily printed recycling and pelletizing.

SPECIFICATIONS

Machine Model:ACS-Pro

Target Recycled Material:HDPE,LDPE,PP,BOPP,CPP,OPP,PA,PC,PS,PU,ABS

Final Product Shape:Particles

System composition:Belt Conveyor, Air Exhausting Device, Sliding Gate, Cutting Compactor with Inverter, Single Screw Extruder, Filtration first,Vacuum Degassing, Pelletizer, Water Cooling Device, Dehydration Section, Conveyor Fan, Product Silo.

Output Range:320kg/h-2100kg/h

Feeding Device:Belt Conveyor (Standard), Roll Hualing off device (Optional)

Compactor Volume:800L-2800L

Diameter of screw:100mm-180mm

Material of screw:Bimetal

L/D of screw:50/ 1

Heater of barrel:Ceramic heater or Far-infrared heater

Cooling of Barrel:Air cooling of fans through blowers

Vacuum deashing exhaust:Two Double-zone vacuum degassing system (Standard)

Pelletizing type:Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing

Voltage Standard:According to the Voltage of the Customer's Location

Optioanl device:Metal detector, Roll hualing off device, Masterbatch and additives feeder

Warranty:13 months from the date of bill of lading

Technical services:project design, factory construction, installation and recommendations, commissioning

VIDEO

Catalogs

ACS-Pro Pelletizing Machine

3 Pages

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Pipe extrusion line

- Twin-screw screw extruder

- Rotor pelletizer

- PVC extrusion line

- Polypropylen extrusion line

- Multilayer extrusion line

- Plastic pelletizer

- Polyethylene extrusion line

- Waste granulator

- Single-screw screw extruder

- Compact pelletizer

- HDPE extrusion line

- Compounding screw extruder

- Drainage pipe extrusion line

- PP screw extruder

- PVC screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.