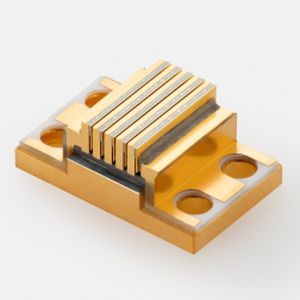

Laser light source L16480 seriesUVfor fiber optics

Add to favorites

Compare this product

Characteristics

- Illumination technology

- laser

- Spectrum

- UV

- Technical applications

- for fiber optics

- Output power

9 W, 30 W

(0.01224 hp, 0.04079 hp)- Wavelength

650 nm, 915 nm, 940 nm

Description

Laser heating system that consists of an optimum light source (SPOLD® LD irradiation light source), fiber and lens for thermal curing of adhesives.Number of process can be reduced by heating and curing the bond part directly with a laser or indirectly by heat conduction. It also allows for highly flexible process design, such as jig-free and manpower saving during complete curing.

Flexible product design possible

Unlike UV adhesives, thermosetting adhesives do not require direct laser irradiation to the adhesive. The adhesive can be cured by heat conduction by heating the surrounding area. It enables a variety of bonding that are difficult with UV adhesives, such as small area where light is hard to reach, backside of materials and black adhesives.

Process improvement

The use of fast curing adhesives that match to the characteristics of laser, which can be heated at high speed, eliminates the need for a heating furnace and can be expected to save a significant amount of energy. In addition, the heating furnace is a batch process and it is difficult to adjust the production volume, but the use of a laser enables a serial process and production adjustment becomes easier. Even for general thermosetting adhesives that do not cure quickly, the use of temporary curing by laser eliminates the jig and the time and man-hours required to set the workpiece in the jig.

Catalogs

No catalogs are available for this product.

See all of HAMAMATSU‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Glass lens element

- SMT LED

- HAMAMATSU LED light source

- HAMAMATSU visible light source

- Spectrum lens element

- Lighting LED

- HAMAMATSU power LED

- Lamp illuminator

- Visible lens element

- Optical lens element

- HAMAMATSU photodiode

- BK7 lens element

- HAMAMATSU compact light source

- Round LED

- HAMAMATSU ultraviolet light source

- Square LED

- Spherical lens element

- HAMAMATSU PIN photodiode

- Infrared illuminator

- Laser diode

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.