- Machine-tools

- Machine Tool Accessory

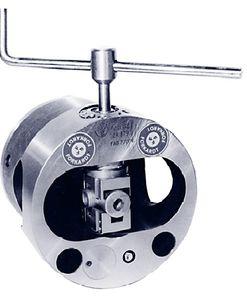

- Hydraulic chuck

- ITW Workholding

Workpiece hydraulic chuck HSR

Add to favorites

Compare this product

Characteristics

- Other characteristics

- workpiece

Description

The production and machining of workpieces with intersecting axes requires a clamping solution that is adapted to the special features of such workpiece types. FORKARDT’s economical solution consists of hydraulically operated indexing chucks, which offer all the prerequisites to remain independent of special machines and transfer lines.

The straightforward design, simple control and flexible mounting options of these indexing chucks allow them to be used on relatively simple turret or NC lathes. Workpieces can be machined in one clamping with fully automatic work sequence and with up to 6 different indexing positions while the machine spindle is running!

Tenon cross machining

Valves and Fittings

tripod production

Crossbeam processing: For the machining of crossbores, small and medium size, the turning accuracy of the roughing process is generally sufficiently precise. For very large spigots, such as Compensation stars with a total length of 300 mm and more, the turnover accuracy can be improved by sizing.

Valve processing: For the production of valve parts in small and medium lot sizes, the use of automatic

Swivel chucks already starting from a dimension of more than 1 “economically interesting. The reason is in addition to the rational relationship of

Setup at peak times in the more effective utilization of the machines.

Catalogs

N.A. Woodworth Product Line

4 Pages

FORKARDT CATALOG

212 Pages

Related Searches

- Chuck

- Milling chuck

- Collet chuck

- DIN chuck

- 3-jaw turning chuck

- Workpiece clamping chuck

- High-speed chuck

- Quick-change chuck

- Lathe turning chuck

- Modular chuck

- Manual turning chuck

- Machining turning chuck

- Milling collet chuck

- Precision turning chuck

- Hydraulic chuck

- Machining collet chuck

- Radial chuck

- Through-hole turning chuck

- Precision collet chuck

- Locking clamp chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.