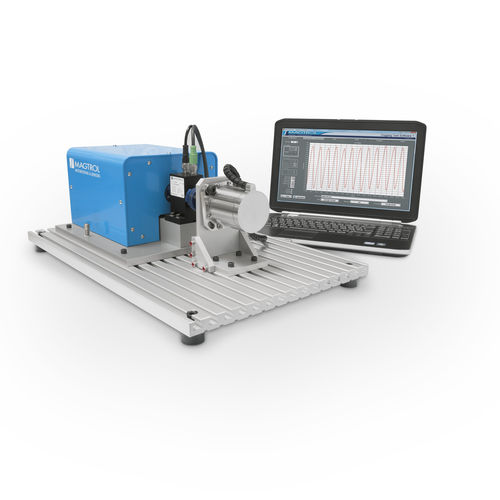

Motor cogging test system CTS Serieslaboratoryfor aerospace applicationsfor automotive applications

Add to favorites

Compare this product

Characteristics

- Domain

- laboratory, for automotive applications, for aerospace applications

- Applications

- for electric motors

- Configuration

- compact, modular, on site

- Options

- for motor cogging

Description

Magtrol’s Cogging Test System is a stand-alone test system designed to control and measure Detent Torque, Cogging Torque and Friction Torque. The test System includes a precision geared motor, a TS Series Torque Sensor integrating a 5 000 pulses encoder. CTS 100 to CTS 102 have a built-in security clutches to avoid system overload by mishandling when not in use. The geared motor drives the MUT (Motor Under Test) at a low speed from 1 to 10 rpm (respectively 8 rpm for CTS 103 and CTS 104), while acquiring its cogging torque related to angle position. The torque measurement covers a range up to 1 N∙m (depending on the selected torque sensor) with an accuracy of ± 0.1 mN∙m (for TS 100 – 50 mN∙m and TS 101 – 100 mN∙m). The executable software controls the system and displays acquired data. It provides accurate peak-to-peak measurement of cogging torque and displays X-Y or polar graphs as well as FFT analysis. The software allows the storage of measured data and provides comparison of performance data by overlaying up to 5 graphs. A cursor can be used to read accurate values from measurement points. Measured parameters can be saved as text file TXT. For better accuracy and function control, the software includes a zero offset adjustment routine which checks transducer signal over a complete turn (test sample MUT not connected to the system).

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

The Battery Show - Europe 2024

18-20 Jun 2024 Stuttgart (Germany) Hall 9 - Stand 9-C73

More information

Related Searches

- Measuring device

- MAGTROL test bench

- MAGTROL automatic test bench

- Digital measuring device

- Portable measuring device

- MAGTROL computer-controlled test bench

- MAGTROL industrial test bench

- Industrial gauge

- Test set

- MAGTROL manual test bench

- Automatic measuring device

- Benchtop measuring device

- MAGTROL universal test bench

- MAGTROL test bench for the automotive industry

- Measuring device with display

- Vertical test stand

- Compact measuring device

- Laboratory measuring device

- MAGTROL multi-parameter test bench

- High-precision measuring device

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.