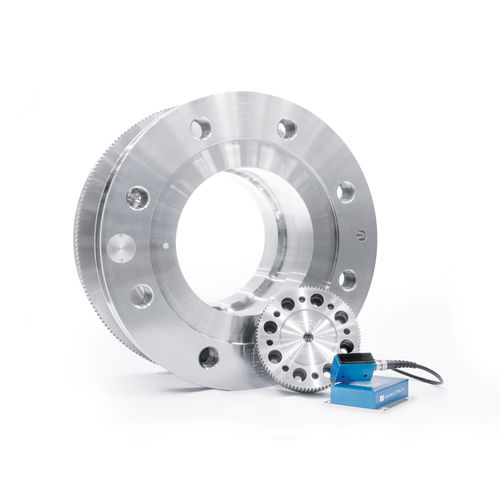

Torque sensor with flange connection TF 300 Seriesrotaryhigh-accuracycustom

Add to favorites

Compare this product

Characteristics

- Type

- rotary

- Configuration

- with flange connection

- Other characteristics

- high-accuracy, custom, high-resolution

- Torque

Max.: 150,000 Nm

(110,634.32 ft.lb)Min.: 20 Nm

(14.75 ft.lb)- Precision

0.1 %, 0.2 %

- Rotational speed

Max.: 20,000 rpm

(125,664 rad.min-1)Min.: 3,500 rpm

(21,991 rad.min-1)- Overload limit

200 %

Description

Product Description

With its compact, bearingless, maintenance-free design, the new TF Torque Flange Sensor from Magtrol brings many appealing advantages to torque measurement applications. The TF’s high torsional rigidity supports direct mounting on the machine shaft or flange, avoiding the use of couplings on one side. This allows easy integration into a test system, shortens the overall length of the test bench and reduces costs.

Based on strain-gauge technology, the TF Sensor’s precise telemetry system enables highly accurate signal transmission. A signal amplifier mounted in the measuring flange amplifies the measuring signal, modulates it to high frequency and transmits it inductively (via the HF transmitter) to the receiver. In the receiver, the digitized torque signal is transformed into an analog output signal of ±10 VDC. Rotational speed can be measured and converted to a TTL output signal with the optional speed pickup.

The contactless design of the Torque Flange Sensor permits a gap of up to 5 mm (typically 1 to 3 mm) between the rotor antenna and HF transmitter, which makes the signal acquisition insensitive to any axial or radial misalignment. Another advantage of this torque measurement system is its insusceptibility to signal interference—due to the fact that, unlike other designs, the antenna does not need to be looped around the sensor. Additionally, a protective cover can be mounted close to the sensor with no effect on the signal.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

The Battery Show - Europe 2024

18-20 Jun 2024 Stuttgart (Germany) Hall 9 - Stand 9-C73

More information

Related Searches

- MAGTROL load cell

- MAGTROL tension/compression load cell

- MAGTROL steel load cell

- MAGTROL strain gauge load cell

- MAGTROL stainless steel load cell

- Weighing force sensor

- Beam type force transducer

- MAGTROL compression load cell

- IP67 force transducer

- Aluminum force sensor

- IP65 force sensor

- Shear beam load cell

- Analog force sensor

- High-precision force sensor

- Compact force sensor

- Hopper resistive load cell

- Torque transducer

- Tension force sensor

- Signal conditioner

- Force gauge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.