- Machine-tools

- Cutting Tool

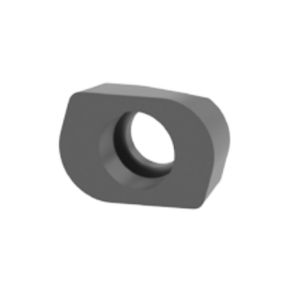

- Milling cutting insert

- POKOLM Frästechnik GmbH & Co. KG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Milling cutting insert M35 PCTCcarbidefor titaniumround

Add to favorites

Compare this product

Characteristics

- Function

- milling

- Material

- carbide

- Treated material

- for titanium

- Other characteristics

- round

Description

Further extremely wear-resistant M35 PCTC cutting materials

High-performance M35 PCTC cutting materials for the machining of titanium and high-temperature alloys

Since the new cutting materials of M35 carbide with PCTC coating were introduced to the market last autumn, they have been convincing the cutting branch especially in the machining of titanium and high-temperature alloys.

That is no surprise because the high temperature stability of M35 carbide guarantees the extraordinarily long-lasting sharpness of the cutting edges. Thanks to its innovative design and coating thickness, the PCTC coating provides exceptional wear resistance as an additional feature. This special combination of carbide and coating additionally enables high cutting rates and feedrates.

New possibilities for further milling cutter bodies

To be able to meet the market demands for such high-performance cutting materials, the range of these inserts will now be extended for further POKOLM milling systems.

Cutting materials with the POKOLM marking „8099“ are available in the following variants as of now:

Round inserts: r 3,5, r5, r6 and r8 mm

SLOTWORX® M: Shoulder face milling inserts r 0.8 / 1 / 2 and 3 mm, high-feed inserts r 1.4 mm

SLOTWORX® L: Shoulder face milling inserts r 1 / 2 / 3 / 4 and 5 mm

As of now, you can order all cutting materials from your technical applications consultant or through the online shop.

Catalogs

Indexable inserts "M35 PCTC"

2 Pages

Other POKOLM Frästechnik GmbH & Co. KG products

Indexable Inserts

Related Searches

- Milling tool

- Solid milling tool

- Steel milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Milling tool with cylindrical shank

- Metal milling tool

- Insert milling tool

- End mill milling tool

- Indexable cutting insert

- Coated milling cutter

- Cast iron milling tool

- Cutting milling tool

- Hemispherical milling cutter

- General purpose drill bit

- Shell-end milling tool

- Roughing milling tool

- Face milling tool

- Corner radius milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.