- Products

- Catalogs

- News & Trends

- Exhibitions

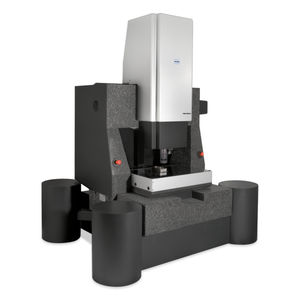

Gantry coordinate measuring machine VideoCheck® HA bridgefor large partsfor crankshafts

Add to favorites

Compare this product

Characteristics

- Structure

- bridge, gantry

- Applications

- for large parts, for gears, for crankshafts

- Probe type

- multi-sensor, optical

- Other characteristics

- high-precision

- X travel

Min.: 400 mm

(16 in)Max.: 1,000 mm

(39 in)- Y travel

Min.: 400 mm

(16 in)Max.: 2,000 mm

(79 in)- Z travel

Min.: 200 mm

(8 in)Max.: 600 mm

(24 in)

Description

Perfectly integrated multi-sensor systems

The VideoCheck® HA is the highly accurate variant of the VideoCheck® FB and can also be equipped with several independent sensor axes (rams). The design with fixed bridge decouples the two movement axes and the scales of all three axes can be arranged centrally, which, in combination with the high rigidity of the design, leads to low measurement uncertainties. In addition, the machine is easily accessible and can be fed from four sides. The machine has a wide range of applications.

• If the specified length measurement error is adhered to, the air bearing granite measuring stage can be loaded with up to 100 kg or optionally with 250 kg

For measurements on particularly heavy workpieces, it is possible to remove the transmitted light unit

• Independent sensor axes allow optimal utilisation of the measuring range, for example, the SP80 tactile sensors and a rotary/tilt head can be interchanged with the SP25 3D scanning probe on the same ram, while the second ram is equipped with optical and tactile-optical multi-sensor systems

• Reduction of the risk of collision between sensors and workpiece

• A second ram can also be retrofitted at a later date

VIDEO

Catalogs

The Multisensor

20 Pages

Related Searches

- Measuring machine

- Touch probe head

- Optical measuring machine

- Laser scanning system

- Measurement scanning system

- Automatic measuring machine

- High-precision measuring machine

- Measurement touch probe head

- CMM

- Parts measuring machine

- Distance measuring machine

- Inspection scanning system

- Laser measurement system

- High-speed scanning system

- Multi-sensor coordinate measuring machine

- Video measuring machine

- 3D measuring machine

- Length measuring machine

- Bridge coordinate measuring machine

- XY scanner

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.