- Products

- Catalogs

- News & Trends

- Exhibitions

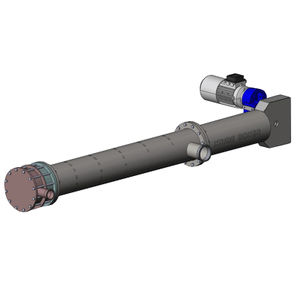

Multi-tube heat exchanger XLG® MDliquid/liquidstainless steelsanitary

Add to favorites

Compare this product

Characteristics

- Type

- multi-tube

- Fluid

- liquid/liquid

- Material

- stainless steel

- Other characteristics

- sanitary, sterile

- Applications

- for the food industry

- Operating pressure

10 bar

(145.04 psi)- Temperature

Max.: 180 °C

(356 °F)Min.: -40 °C

(-40 °F)

Description

Multi-tube heat exchangers developed for hygienic/sanitary product to product heat recovery applications in the food, dairy and beverage industry. The fluids may also contain limited quantities of pulp and/or fibres.

XLG®MD Regenerative Multitube heat exchangers are manufactured entirely from stainless steel and consist of a bundle of corrugated tubes mounted within a corrugated outer tube (which forms the outer shell).

The sterile fluid flows through the interior of the tubes forming the tube bundle and the raw (not-sterile) fluid outside the inner tubes, through the shell.

All product wetted surfaces, including the welds, have a surface roughness Ra < 0.8 µm and are therefore able to process food products under the normal hygiene regulations. Such processes include pasteurisation, high temperature sterilisation, thermal treatment for aseptic packaging etc.

Both fluids (sterile and not-sterile) are completely isolated from each other, heat transfer taking place across the inner tube walls. Leakage of the service fluid to atmosphere is prevented by a pair of elastomeric O ring seals at each end of the tube. If hygiene and process conditions require it steam packing can be provided between the O ring seals at both ends of the units

Related Searches

- Heat exchanger unit

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Tubular heat exchanger

- Stainless steel heat exchanger

- Gas/liquid heat exchanger unit

- Industrial heat exchanger

- Shell and tube heat exchanger

- Heat exchanger for the food industry

- Titanium heat exchanger

- Nickel heat exchanger

- Pressure heat exchanger

- Heat exchanger for the pharmaceutical industry

- High-pressure heat exchanger

- High-temperature heat exchanger

- Scraped surface heat exchanger

- Sanitary heat exchanger

- Multi-tube heat exchanger

- Viscous product heat exchanger

- Tube-tube heat exchanger

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.