- Machine-tools >

- Machining Center >

- CNC lathe

CNC lathe

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Diameter: 100 mm

Spindle speed: 1,500 rpm

The simplicity for the turning of prototypes and small series, the technology for the performance The strengths • ISO programming, industry standard. • Allows the main turning operations (trimming, turning grooving, boring, drilling, ...

Diameter: 200 mm

Spindle speed: 100 rpm - 3,000 rpm

Maximum part length: 280 mm

The LabTurn is suitable for CNC training as well as for the production of small workpieces. The compact and mobile CNC lathe represents the full range of functions of a large production ...

Knuth Machine Tools

Maximum part length: 1,000 mm

Bar capacity: 58 mm

Axe X: 285 mm

The turning machines of the Turnado series are characterized by their robust construction, powerful motor and versatility. For more than 20 years they have been among the tried and tested bestsellers of our conventional ...

Knuth Machine Tools

Diameter: 400 mm

Spindle speed: 50 rpm - 2,000 rpm

Maximum part length: 430 mm

This machine of the ROTURN C series impresses with the classic virtues of a compact CNC production lathe. With its Siemens 828 D Basic control, it meets all the requirements for current control technology. ...

Knuth Machine Tools

Diameter: 419 mm

Spindle speed: 6,000 rpm

Bar capacity: 44 mm

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability. The ST-10Y has an extra-small footprint, yet provides ...

Haas Automation

Diameter: 419 mm

Spindle speed: 4,000 rpm

Bar capacity: 64 mm

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability. The ST-15Y is an extra-small footprint, big-bore lathe ...

Haas Automation

Diameter: 254 mm

Spindle speed: 4,000, 4,500 rpm

Axe X: 239 mm

The DS-30Y Y-axis turning center combines dual-spindle turning with Y axis, C axis, and live tooling to create a powerful “done-in-one” machining solution for any shop. Off-center milling, drilling, and tapping operations ...

Haas Automation

Spindle speed: 0 rpm - 7,000 rpm

Maximum part length: 480 mm

Maximum cutting diameter: 300 mm

HIGHLIGHTS / Highly dynamic drives in all axes / Two high-performance work spindles / Two highly flexible, 12-station tool turrets / Stable Y-axis with 70 mm travel / State-of-the-art control and drive technology / User-friendly ...

EMCO GmbH

Diameter: 0 mm - 500 mm

Spindle speed: 3,500, 4,000 rpm

Maximum part length: 1,040 mm

EQUIPMENT / CNC machine turning with main and counter spindle in three spindle sizes ø65 ( ø76,2/ø95) mm / Milling spindle with tool changer, 40-fold tool magazine HSK-T63, B- and Y-axis / Additional two tool turrets ...

EMCO GmbH

Diameter: 114 mm

Spindle speed: 0 rpm - 8,000 rpm

HIGHLIGHTS / Large speed range / Counter spindle for complete machining / Driven tool positions / Stable Y axis / High rapid-motion speeds / Best machining quality / Compact machine construction / Made in the Heart of Europe EQUIPMENT / ...

EMCO GmbH

Diameter: 315 mm

Spindle speed: 0 rpm - 4,000 rpm

Maximum part length: 750 mm

... the axis Star turret and compound slide setup / Disc turret Machining possible up to 70 mm below turning center 6,000 rpm, 8.8 kW, 19.5 Nm (25%) NC tailstock electronically freely positionable generously ...

INDEX Drehmaschinen

Diameter: 400 mm

Spindle speed: 0 rpm - 3,150 rpm

Maximum part length: 1,200, 750 mm

... work area concept Rigid mineral cast bed in 45° block design for high accuracy Work spindle with belt drive for high torques NC tailstock with electrically controlled axis Already included: the operating system iXpanel ...

INDEX Drehmaschinen

Spindle speed: 0 rpm - 6,000 rpm

Maximum part length: 200 mm

Bar capacity: 65 mm

Machine highlights Your benefits Y axis-functionality for surface milling and off-center drilling Compact design and high performance with minimal floor space requirements Spindle clearance up to 65 mm Reduced cycle time through ...

INDEX Drehmaschinen

Diameter: 1,040 mm

Spindle speed: 1,600 rpm

Rapids on X: 20,000 mm/min

... for this turning center class. Chucker version is also available. The MAZATROL SmoothC CNC sytem, designed for unsurpassed ease of operation, is standard equipment. MAZATROL SmoothG is optionally ...

Mazak

The range of big-sized vertical lathes VERTIGO represents the new reference point of the sector. FPT decade-long planning and technological experience in manufacturing big-sized hydrostatic borig machines , finds a new ...

Diameter: 315 mm

Spindle speed: 4,000 rpm

Maximum part length: 750 mm

... belt drive for high torques Bar capacity dia. 82 mm, chuck up to dia. 315 mm Orthogonal, linear Y-axis for high accuracy NC tailstock with electrically controlled axis Already included: the operating system iXpanel ...

INDEX FRANCE

Diameter: 400 mm

Spindle speed: 3,150 rpm

Maximum part length: 750, 1,200 mm

... belt drive for high torques Bar capacity dia. 102 mm, chuck up to dia. 400 mm Orthogonal, linear Y-axis for high accuracy NC tailstock with electrically controlled axis Also available as long version: turning lenght ...

INDEX FRANCE

Diameter: 315 mm

Spindle speed: 4,000, 6, 5,400 rpm

Bar capacity: 82 mm

... consistent further development of proven production solutions from TRAUB. Individually equipped, this new flexible universal lathe takes its place both in tooling and prototyping, but also in medium and large series production. ...

INDEX FRANCE

Diameter: 150 mm - 650 mm

Spindle speed: 400, 500, 600 rpm

Axe X: 15,000 µm

This is a horizontal turning lathe that is used for precise grooving on the roll for optical sheet molding. The following features are equipped to obtain high-precision machine movement and machining accuracy. High-precision ...

Shibaura Machine

Diameter: 34, 42 mm

Spindle speed: 50 rpm - 6,000 rpm

Axe X: 140 mm

Simultaneous left/right processing with a main turret and compact sub-turret and overlap processing with double turning tools sharply cut the machining time A half-indexing mechanism and a tool holder that can be fitted with complex ...

CITIZEN MACHINERY MIYANO CO.,LTD

Diameter: 313.7, 226.3 mm

Spindle speed: 6,000, 5,000, 4,000 rpm

Bar capacity: 42, 51, 65 mm

The Hardinge SUPER-PRECISION® T-Series turning centers set the standard in high-precision and high-performance turning that will take your part quality and manufacturing capabilities to new heights. T-Series machines ...

Hardinge Bridgeport

Diameter: 455.6, 298.7 mm

Spindle speed: 8,000, 5,000 rpm

Bar capacity: 27, 42 mm

Hardinge QUEST Series turning centers are designed for the quick changeovers you need to dramatically reduce setup and cycle times. QUEST Series machines include our patented, interchangeable top plates that you can pre-tool ...

Hardinge Bridgeport

Diameter: 550 mm

Spindle speed: 6,000, 5,000 rpm

Maximum cutting diameter: 290 mm

The newly upgraded Hardinge® TALENT multi-tasking CNC lathes: Now proudly made in the USA, with US and global components Hardinge® Talent® Series multi-tasking CNC lathes ...

Hardinge Bridgeport

Diameter: 320 mm

Spindle speed: 4,000 rpm

Maximum cutting length: 303 mm

with a 6 inch chuck, enables the machining of round, circular workpieces. Highlight Easy to Operate Reliability Shortened Machining Time A small footprint with big capabilities The largest machining area in its class. User ...

DN SOLUTIONS

Diameter: 350 mm

Spindle speed: 5,000 rpm

Bar capacity: 54 mm

monobloc base Rigid linear guide with preloaded saddle Cartridge spindle with super precision ball bearings, lubricated for life. Chuck and tailstock (manual, pneumatic or hydraulic) Automatic turret Grinded ballscrews and double ...

SOMAB

Diameter: 410 mm

Spindle speed: 5,000 rpm

Bar capacity: 52 mm

... Fix steady rest with 3 rollers for Ø60mm to 150mm DELIVERABLE: isolation transformer toolholders clamping pliers CNC Learning SOMAB PL + S VT 15" color LCD flat touch screen QWERTY alphanumeric keyboard Two ...

SOMAB

Diameter: 500 mm

Spindle speed: 4,500 rpm

Bar capacity: 73 mm

... Fix steady rest with 3 rollers for Ø80mm to 200mm DELIVERABLE: isolation transformer toolholders clamping pliers CNC Learning SOMAB PL + S VT 15" color LCD flat touch screen QWERTY alphanumeric keyboard Two ...

SOMAB

Diameter: 0 mm - 200 mm

Created to carry out internal and external surface operations and facing operations on the ends of non-rotating fixed tubular bodies, unable to be operated by the conventional machine tools. Suitable for the all the severals, complex ...

Diameter: 0 mm - 400 mm

Spindle speed: 0 rpm - 143 rpm

Axe Z: 200, 320 mm

Created to carry out internal and external surface operations and facing operations on the ends of non-rotating fixed tubular bodies, unable to be operated by the conventional machine tools. Suitable for the all the severals, complex ...

Diameter: 170 mm

Spindle speed: 6,500 rpm

Maximum part length: 200 mm

The Famar Ergo 200 vertical lathe is the perfect machine tool for turning mechanical parts of all shapes and materials up to 170 mm. Extremely stable and precise, the Ergo 200 offers the best technical performance, guaranteeing ...

Famar Srl

Diameter: 260 mm

Spindle speed: 5,300 rpm

Maximum part length: 240 mm

... the Tandem 260 lathe offers turning processes with two different machining operations or high volume standards, as the Tandem family duplicates the production normally provided by the Ergo range. The Famar Tandem ...

Famar Srl

Diameter: 260 mm

Spindle speed: 5,300 rpm

Maximum part length: 240 mm

The Famar Ergo 260 vertical lathe is the perfect machine tool for turning mechanical parts of all shapes and materials up to 170 mm. Extremely stable and precise, the Ergo 260 offers the best technical performance, guaranteeing ...

Famar Srl

Maximum part length: 200 mm - 1,000 mm

Maximum cutting diameter: 20 mm - 80 mm

The CNC lathe 4TF/1000 stands out in the field of milling, revolutionizing productivity with its ability to simultaneously work four pieces. Thanks to its advanced numerical control (CNC) ...

Diameter: 2,400, 3,200, 2,000, 1,600, 2,800 mm

Spindle speed: 200 rpm - 6,000 rpm

Maximum cutting diameter: 1,250 mm - 3,000 mm

The Pietro Carnaghi vertical turning centre model AC is designed and built in a compact form, with an extremely rigid thermo symmetrical structure, having the column mounted to the table base. All these elements are assembled together ...

PIETRO CARNAGHI

Diameter: 3,600 mm - 6,500 mm

Spindle speed: 60 rpm - 6,000 rpm

Axe Z: 1,250 mm - 3,000 mm

The Pietro Carnaghi vertical turning centre model AC is designed and built in a compact form, with an extremely rigid thermo symmetrical structure, having two columns mounted to the table base. All these elements are assembled together ...

PIETRO CARNAGHI

Diameter: 7,000 mm - 14,000 mm

Spindle speed: 35 rpm - 6,000 rpm

Axe Z: 2,000, 2,500, 3,000, 3,500, 4,000 mm

Model AP is characterized by a structure with 2 columns, designed for large parts, up to 14 meters (45.9 ft) of part diameter. The structure of the machine is a “formation” having the columns mounted to the table base, housing the main ...

PIETRO CARNAGHI

Diameter: 1,600 mm - 8,500 mm

Spindle speed: 2,500, 3,000, 4,000, 4,500, 5,000 rpm

Axe Z: 3,000, 1,200, 2,500, 2,000, 1,500 mm

Table diameter mm 1.250/1.400/1.600/1.800/2.000/2.200/2.500/3.000/3.200/3.500 4.000 Maximum load kg 12.000/15.000/25.000/35.000/50.000/60.000 Table speed min-¹ 440/325/300/275/250 / 180/ 150/ 128 Standard turning height mm 1.600/2.000/2.800 Option ...

Diameter: 2,000 mm - 6,300 mm

Axe Z: 2,000, 1,500, 1,200 mm

Rapids on X: 10,000 mm/min

Table diameter mm 1.600/2.000/2.500/3.000 Maximum load kg 10.000/15.000/20.000/30.000 Table speed min-¹ 300/ 220/ 176/ 150 Standard turning height mm 1.600/2.000/ 2.400 Option of different turning heights mm 2.000/2.400/2.800/3.200 RAM ...

Diameter: 10,000 mm

Spindle speed: 5,000, 4,500 rpm

Axe Z: 3,500, 3,000 mm

Table diameter mm 8.000 Maximum load kg 350.000 Table speed min-¹ 50 Standard turning height mm 5.000 Option of different turning heights mm 5.500 / 6.000 RAM section mm x mm 560 X 560 Min. RAM bore size mm 600 Milling power kW 63 60

Diameter: 0 mm - 620 mm

TECHNICAL CHARACTERISTICS - FNL 220-LSMC Control - FANUC 0i-TF controller (8.4 ") COLOR TFT LCD Travel axis X - 220 mm Travel axis Z - 560 mm Max. Vaulting - 620 mm Max turning diameter - 330 mm Max turning length - 510 mm Spindle nose ...

Diameter: 300, 800 mm

Spindle speed: 0 rpm - 24,000 rpm

Axe X: 500 mm

Wood CNC Lathe is also called CNC Turning Machine, now it is for sale at the best price. Wood CNC Lathe machine is suitable for processing workpieces ...

Diameter: 300 mm

Spindle speed: 0 rpm - 18,000 rpm

Axe Z: 300 mm

This CNC lathe has the advantages of high processing efficiency, high processing precision and high intelligence. It can quickly change from processing one part to processing another part, so it provides ...

Axe X: 1,300 mm

Axe Z: 2,500 mm

Nominal power: 3.5, 9 kW

This is a CNC wood lathe turning machine with automatic tool change. There is no need to stop working during the processing, and there is no need to manually change the tool, which greatly ...

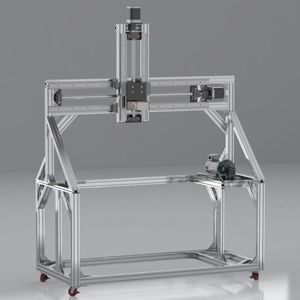

Diameter: 152 mm - 304 mm

Maximum part length: max 1016.0 mm

Nominal power: 2 ch

Custom Manufacturing is a beneficial platform within the subtractive industry. Our CNC Lathe can be customized to the parameters and needs of your specific project. Standard with: - 6062 Extrusion ...

Diameter: 350 mm

Spindle speed: 30 rpm - 2,000 rpm

3-AXIS DISPLAY WITH SPEED VARIATION CONTROL, SEMI NORTON GEARBOX. WITH CAST IRON MONOBLOC BASE. THE COMPUTER-VIEWER VARIES THE ROTATION SPEED ACCORDING TO THE TURNED DIAMETER.

FERVI

Diameter: 320 mm

Spindle speed: 45 rpm - 2,000 rpm

WITH 2 SPEED MOTOR AND 3 AXIS READ OUT, SEMI NORTON GEAR BOX. TURNING BAR WITH ADJUSTABLE CLUTCH.

FERVI

Diameter: 320 mm

Spindle speed: 12 rpm - 2,000 rpm

WITH 2 SPEED MOTOR AND 3 AXIS READ OUT, SEMI NORTON GEAR BOX. TURNING BAR WITH ADJUSTABLE CLUTCH. Centers height 200 mm Max swing over the bed 400 mm Max swing over the cross slide 258 mm Max swing over the gap 550 mm Tool ...

FERVI

... The CNC cutter lathe is an automated computer-controlled device, operated by a stepper motor. It consists of two movable holders mounted on the machine table. Carving using the lathe ...

Diameter: 940, 840, 740, 640 mm

Spindle speed: 0 rpm - 1,800 rpm

M.C.M. MADAR

Diameter: 350, 400, 460, 554 mm

Spindle speed: 1 rpm - 3,500 rpm

Standard Features… Multi-repetitive Cycles G70-G76 for automatic finishing, roughing, drilling, threading and grooving cycles Toolpath Graphics for verification of part profile 10.4" Color LCD Display Inch/metric data input Absolute/incremental ...

Your suggestions for improvement:

CNC, or computer numerical controlled lathes are machine tools whose operation is directed by a computer program.

ApplicationsThese devices are found in aeronautics and the automobile and plastics industries, as well as most other industrial settings.

TechnologiesSuch machines are designed to use carbide tools and the latest manufacturing processes, though configuration resembles that of traditional lathes. The controlling software is the essential element. The machine can be programmed directly on the shop floor or via a CD, diskette, laptop or dedicated network.

Several operational parameters are coded into the program:

- tool position and speed

- position and rotational speed of the spindle holding the workpiece

- delivery of cooling fluid

- loading of raw materials

While design varies with manufacturer, all have points in common. The turret holds the tool holders and indexes them as needed. The spindle holds the workpiece, and the turret moves along several axes simultaneously on slides. For safety, many of these machines are completely enclosed.

- Repeatability

- Precision

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining