- Machine-tools >

- Finishing Machine >

- Grinding machine

Grinding machines

Spindle speed: 3,500 rpm

Power: 2 ch

Distance between centers: 20 in

2 HP V-3 graded spindle motor. 10" x 20" grinding capacity. Double nut design on crossfeed leadscrew for continuous backlash adjustment. 2 axes automatic movement. Safety 24 volt circuit control. ...

Taiwan Trade Center, Chicago

Power: 0.8 kW

Grinding machines for plane knives. Automatic feeding of grinding wheel. Base and cooling system included. Frame very strong to absorb the vibration during grinding operations. Knives ...

VISCAT FULGOR

The SETCO!" Spark Erosion Grinding (SEG) System is a portable electronic discharge machining system that precisely removes metal stock using AC current. The SEG process utilizes EDM technology ...

Stationary grinding and lapping machines for machining sealing faces in gate valves, valves, safety valves, non-return valves, wedges, etc. Main components: • Robust pedestal with ...

EFCO Maschinenbau GmbH

Spindle speed: 1,450 rpm

Power: 4 kW

Surface worktable 600x300 Maximum rectification area (mm) 600x300 Maximum longitudinal travel of table (mm) 660 Maximum cross travel of the table (mm) 370 Maximum distance between the spindle centre/ table (mm) 540 Maximum load ...

HELLER MAQUINA HERRAMIENTA, S.L.

Spindle speed: 0 rpm - 8,000 rpm

... 300 Max swivel angle of grinding head ±45° Max tool shift stroke for generating grinding(mm) 120 Max grinding spindle revolution(min-1) 8000 Max work table rotation (min-1)1000 Required ...

... metals without heat. An 8" diameter contact wheel as well as a 24" long platens are fitted aiding in the machines' operational process. These machines are equipped with a manual switch and are mounted ...

Power: 0.8 kW - 20 kW

CENTERLESS GRINDING MACHINES We can offer all kinds of grinders full or partially automated centers to meet their needs. No matter if you want a continuous production process or plongee. R 605 CNC ...

... segment. The advantages of GEORG roll grinding machines - High precision and grinding power are the characteristic features of the GEORG roll grinding machines. - ...

The horizontal flat-grinding machine is earmarked for the cold working of flat surfaces of glass and ceramic articles, stone, etc. Hand-held articles are pushed against the top surface of the abrasive ...

BOHEMIA MACHINE

... completely and instantly. A feeder arm feeds the blade forwards, and a clamp, which is fitted to the blade, turns the machine off when the blade has been sharpened in one turn. It can be adjusted for tooth rake angle, ...

Power: 16.8 kW - 22 kW

... two-sided deburring and edge rounding of punched, laser and fine plasma cut workpieces using only one work process. Unlike grinding machines, SBM-L G1S2s win over customers with more efficient processing ...

LISSMAC

possibility to produce concave shapes by use ofadditional high révolution spindleattachment for making templatesquick clamping of the doppossibility to work with water circulation

AVALON

Spindle speed: 3,000 rpm

Power: 1.5, 2.2 kW

Tamis machinery co.

X travel: 2,600 mm

Y travel: 380 mm

... Dressing unit X2-axis140 mm Y2-axis143 mm Y3-axis155 mm Grinding head TypeS500 Power93 kW S1 Wheel mountØ 165 mm Grinding disk diameter min.220 mm Grinding disk diameter max.500 ...

... -Löffler machines, they are also suitable for use in building and construction. Following are examples of machines presented for this branch of manufacture. We gladly provide individual consultation and ...

Power: 3 kW

... belt tensioning system simplifies tensioning the grinding belt. The belt is tensioned using the hexagonal spanner supplied with the machine. The grinding belt can be tensioned quickly ...

ALMI Machinefabriek BV

... workmanship of the sharpener guarantees an accurate saw blade sharpening – the basic condition for productive and quality cutting on any bandsaw mill. The stone grinding wheel is a thin grinding ...

Pilous

The main machine of the flour milling equipment in the flour mill mainly peels the wheat by a pair of grinding rollers with speed difference and relative rotation, peels ...

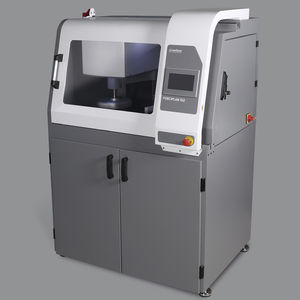

Spindle speed: 2,500 rpm

Power: 2.53 kW

X travel: 480 mm

... and light surface grinding work is also possible with this model. With the additional tool grinding function area, you can use the Multi Grind to machine the cutting edges of a large ...

Knuth Machine Tools

Spindle speed: 500 rpm - 3,500 rpm

Power: 3.7 kW

X travel: 560 mm

... flute grinding. This machine offers advantages in terms of precision and efficiency thanks to grinding cycles that can be easily programmed via the touchscreen and the automatic grinding ...

Knuth Machine Tools

Spindle speed: 500 rpm - 2,300 rpm

Power: 3.7 kW

Distance between centers: 640 mm

... flute grinding. This machine offers advantages in terms of precision and efficiency thanks to grinding cycles that can be easily programmed via the touchscreen and the automatic grinding ...

Knuth Machine Tools

Spindle speed: 3,000, 2,810 rad.min-1

Power: 2.5 kVA

... changes the way you monitor and manage your turret tooling inventory. ID-TOGU digital management provides optimal grinding by taking grinding values from AITS server automatically. Easy and simple to ...

Spindle speed: 3,000 rad.min-1

Power: 1.5 kW

Distance between centers: 80 mm

Cut down on grinding times and extend the lifetime of your tools. Quick, reliable grinding of all standard tooling, the TOGU-EU restores tooling to optimum condition resulting in high quality parts.

Spindle speed: 1,380 rpm

Power: 2.2 kW

Surface grinding machine - SM280 Highly efficient range of grinding machines in 230 V for professional performance in grinding of concrete, natural ...

Power: 2,200 W

Surface grinding machine - SM250 Lightweight - Compact - Easy to use SM250 Grinding machine in 230 V. Made for small jobs in surface preparation GÖLZ Grinding ...

CMF Groupe has already realized a variety of metal sheet working machines with high speed and high precision. We customize the machine according to our customers’ needs. Examples : High speed for ...

Spindle speed: 500 rpm - 1,500 rpm

Power: 4 kW

... having 10 specimens can be prepared in less than a minute with 350 mm diameter grinding stone. It can easily provide enough specimens for two or three grinding/polishing machines. Uses ...

Metkon Instruments Inc.

Spindle speed: 1,450, 1,750 rpm

Power: 11 W

Features: Programmable controlled grinding machine Precision spindle and rigid elevating elevating guideways Automatic wheel dressing with compensation (opt.) Completely supported guideways Rigid ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining