- Hydraulics - Pneumatics

- Pump

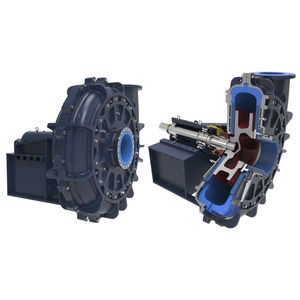

- Slurry pump

- FLSmidth Dorr-Oliver Eimco

Slurry pump millMAX™electriccentrifugalindustrial

Add to favorites

Compare this product

Characteristics

- Fluid

- slurry

- Operation

- electric

- Technology

- centrifugal

- Domain

- industrial

- Applications

- recirculation

- Material

- hard metal, cast iron

- Other characteristics

- suction, adjustable

- Pressure

35 bar

(507.632 psi)

Description

Increased wear life

Lower power consumption

Increased mill throughput

More consistent hydroclone separations

Reduced cost-per-ton pumped

Proprietary-design slurry pump

The key advantages of our efficient millMAX Slurry Pump design are lower power requirements (up to 30% less); long, even wear life; and less pump downtime – all of which result in lower cost-per-ton pumped along with better cyclone separation.

The millMAX difference

The KREBS millMAX Pump’s unique design was developed exclusively for pumping abrasive slurries.

Prior to the millMAX, slurry pumps experienced two major problems: mechanical grinding of solids between the suction liner and impeller, and flow recirculating back to the impeller eye on the suction side. Both of these problems decrease pump life and increase power consumption. Conventional slurry pumps can only solve one of these issues through impeller and liner adjustment – but not both.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.