- Products

- Catalogs

- News & Trends

- Exhibitions

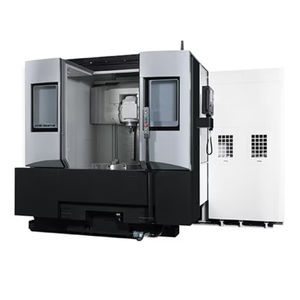

CNC milling-turning center VTM-80YBhorizontalvertical5-axis

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- horizontal, vertical

- Number of axes

- 5-axis

- Structure

- spindle, precision

- Diameter

800 mm

(31.5 in)- X travel

1,120 mm

(44 in)- Y travel

710 mm

(28 in)- Z travel

1,135 mm

(45 in)

Description

Our VTM-80YB 5-axis combination lathe/machining center can perform turning, vertical, horizontal, and angled surface machining in one operation without reorienting the part in the chuck. With operator control of spindle direction in relation to the surface of the workpiece, side cutting with straight end mills can be used to dramatically reduce cutting time compared with point cutting using ball end mills. Cutting efficiency can be increased significantly and the lifetime of the tooling can be extended, reducing overall production costs. The work spindle is supported at two locations by large diameter roller bearings, offering precision control for the production of complex parts. The spindle’s geared head generates high torque capable of sustaining the heavy cutting necessary for parts such as large valve bodies.

Catalogs

No catalogs are available for this product.

See all of OKUMA‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- OKUMA machining center

- OKUMA vertical machining center

- OKUMA lathe

- OKUMA CNC lathe

- OKUMA 3-axis machining center

- OKUMA precision machining center

- 2-axis turning center

- OKUMA 5-axis machining center

- OKUMA high-precision machining center

- Rigid CNC machining center

- High-performance CNC machining center

- OKUMA high-precision lathe

- High-rigidity CNC machining center

- Cutting CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Turning center with turret

- OKUMA 12 tools lathe

- OKUMA 1-spindle lathe

- 3-axis turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.