- Production Machines >

- Plastics Processing >

- Other plastic and rubber transformation machines

Other plastic and rubber transformation machines

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Stäubli quick clamping systems can be used on any machine, new or existing, whether vertical or horizontal loading. Our systems allow you to optimise your production capacity and improve your flexibility and response times. Magnetic ...

Stäubli offers unique expertise for the quick change of moulds in the plastics industry. At K 2019, Stäubli will exhibit its innovative interactive injection moulding cell combining all of its solutions for energy circuits ...

Changing film thickness by push of the button The BREYER calender gap adjustment "fast & easy" does not involve any mechanical adjusting parts. A sophisticated system permits precise and accurate positioning. Amazingly, this precision ...

The Future is Energy. BREYER calender technology for the production of electrode film for lithium-ion batteries The new generation of the BREYER calenders represents a milestone in improving lithium-ion electrode film production. The ...

Model HSR: Devulcanizing Machine What does devulcanization mean? The purpose of HSR (High Shear Regeneration) consists in devulcanizing rubber waste for reintroduction into the production chain. This patented process applies to ...

Low-pressure metering machines for processing cast elastomers When it comes to processing polyurethane-based casting systems and raw materials, the name ELASTOLINE has for decades been synonymous with high-quality end products. Low-pressure ...

The next evolutionary stage in elastomer processing: no material and solvent losses in production with high-pressure technology Elastomer processing under low-pressure has one distinctive disadvantage: for technical reasons, material ...

The ToolingShuttle 61 combines the crimp applicator (tooling), terminal reel and paper winder into one mobile quick-change unit for CrimpCenter 6-series fully automatic crimping machines. The ToolingShuttle 61 allows the operator to exchange ...

Multiple injection molding machines share a set of automatic mold changing trolley system. This “automatic mold changing trolley system” can effectively solve the mold changing operation of large molds, such as stamping parts for automotive ...

Multiple injection molding machines share a set of automatic mold changing trolley system. This “automatic mold changing trolley system” can effectively solve the mold changing operation of large molds, such as stamping parts for automotive ...

Discover the innovative Electro Permanent Magnetic Chuck, designed to deliver unmatched precision and efficiency for your machining needs. This advanced chuck technology combines the benefits of permanent magnets and electromagnets, providing ...

YVROUD calendering lines are generally intended for the development of the continuous manufacturing process for single or multi-layer products. They are mainly installed in research centres, inspection laboratories and training centres. VROUD ...

This technology provides softness, a unified structure, high-durability and design flexibility through a three-layered molding structure consisting of a insert plate, silicon film and a decorated urethane sheet. ◆Designs not possible ...

Ultra-thin decorative sheet with three-dimensional logos and characters Features of this technology Form 3D characters (metal-like) in an ultra-thin sheet (e.g. 0.4mm to 0.5mm) 3D characters (metal-like) have no eff ect on antenna ...

◆Silicone materials possess a high level of environmental reliability. ◆Silicone is biocompatible. ◆Molded shapes area available as molding is conducted using a mold/tool. ◆Combinations with silicone decorations are available. ■Data ...

With customer safety always the top priority at Milacron, we offer a full line of Quick Mold Change products developed to decrease downtime between mold changes. Our solutions include both vertical load and horizontal load style hydraulic ...

- High automation: Automatic rubber material loading, Automatic tension steel belt, Semi-automatic taking out product. - Energy-saving: Hydraulic pump adjusts the energy consumption during curing to avoiding the energy lost. ...

YIZUMI Intelligent Die Casting Island focuses on providing a complete set of turnkey solutions for industrial production processes like robotic automated intelligent manufacturing systems, peripheral equipment, and related technical support ...

Plasticizing systems for injection molding machines must meet many different requirements. These range from processing easy-flowing, semi-crystalline thermoplastics to molding highly reinforced, sluggishly flowing plastics with processing ...

The die-splitter was developed following our customers’ needs to easily handle big moulds, also in the sheet metal sector. The die-splitter is an innovative, versatile and efficient solution, in line with the increasing automation ...

Millutensil

The A90 C system is the right choice for providing material via standard Semco or Euro cartridges, depending on the cartridge size. The system works with compressed air, which pushes the cartridge trigger and feeds the material from the ...

Scheugenpflug GmbH

A parallel lift – No crabbing from side to side The Die Splitter enables one person to safely split and service a die sets and plastic injection mould tools in a safe, controlled and repeatable manner. The Die Splitter and mould splitters ...

Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased ...

With the EAS die splitter or die separator, it is possible to split and open a die, then turn the die half and place the turned die half back on the table. So, a die set can be split and serviced by one person in a controlled, repeatable ...

EAS change systems

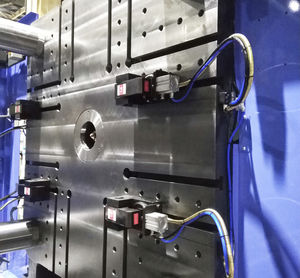

The magnetic clamping system employs two types of strong, permanent magnets eliminating the risk of molds falling due to a loss of magnetic force during power outages. Electric power is only used when the magnetic force is initiated (magnetizing) ...

The superior hot vulcanizing machine. We have perfected our Standard Press over the last 30 years. The machine has been developed to hot vulcanize all types of rubber, for example, EPDM, NBR, SBR CR, NR and without retooling the machine ...

NorMec

• Switching time: 6 - 8 min • Drive line: 400 VAC / 50 Hz • Arm length: Customized • Lift housing: Adaptable to needs • Rail system: A65 Lifting height and dimensions can be customized to fit your specifications

Our rubber devulcanization technology is thermo-mechanical way. Process Process 1: Just do Devulcanization process for the rubber and add 5~10% into the new rubber for new tire or sheet application, without affecting the properties ...

An optimal vulcanization solution for all types of product Lescuyer et Villeneuve offers several vulcanization systems specific to your needs as type of materials, geometry, line speed. Our infrared shock modules stabilize the profile ...

Lescuyer Villeneuve

Vulcanizing presses are used in the creation of rubber jewellery dies. The devices are equipped with two independent aluminum hot plates which guarantee perfect temperature transfer to the vulcanising frame. A characteristic feature of ...

productions of low and medium volumes single mixing head provision production for thermal insulation (panels, refrigerators and packaging) production of flexible foam for furniture productions where it is necessary to ...

ISC ITALY

Your suggestions for improvement:

Subscribe to our newsletter

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining