- Power Transmission - Mechanical components >

- Bearing and Linear Guide >

- Dry plain bearing

Dry plain bearings

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

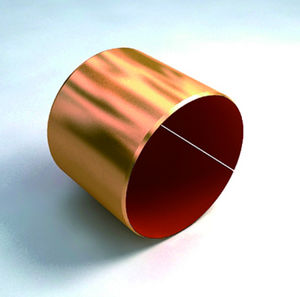

High-performance dry sliding bearing material: deva.metal® deva.metal® is a high-performance sliding bearing material. Manufactured using powder metallurgy, the deva.metal® system ...

Federal-Mogul Deva GmbH

... bronze sliding layer. The solid lubricant (graphite or PTFE) dispersed in the sliding layer under preload enables the sliding bearing to be used without the need for maintenance. The maintenance-free and self-lubricating ...

Federal-Mogul Deva GmbH

deva.tex® 541 is a bearing material consisting only of a sliding layer. The sliding layer consists of a special synthetic fabric and epoxy resin. It achieves outstanding performance thanks to the addition of solid lubricants.

Federal-Mogul Deva GmbH

... lubricants. Thanks to the solid lubricant that is finely distributed in the resin matrix, deva.tex® 542 is suitable for dry operation and also for underwater applications. The base layer (color: beige) consists ...

Federal-Mogul Deva GmbH

... lubricants. Thanks to the solid lubricant that is finely distributed in the resin matrix, deva.tex® 544 is suitable for dry operation and also for underwater applications. The base layer (color: beige) consists ...

Federal-Mogul Deva GmbH

... lubricants. Thanks to the solid lubricant that is finely distributed in the resin matrix, deva.tex® 545 is suitable for dry operation and also for applications with grease lubrication. The base layer (color: orange) ...

Federal-Mogul Deva GmbH

... lubricants. Thanks to the solid lubricant that is finely distributed in the resin matrix, deva.tex® 552 is suitable for dry operation and for underwater applications. The base layer (color: green) consists of glass fibers.

Federal-Mogul Deva GmbH

... lubricants. Thanks to the solid lubricant that is finely distributed in the resin matrix, deva.tex® 558 is suitable for dry operation and also for underwater applications. The base layer (color: dark purple) consists ...

Federal-Mogul Deva GmbH

GLYCO® 92 sliding bearings have a steel backing onto which a 0.2 to 0.4 mm thick porous layer of tin bronze is sintered. This layer's pores are filled with polytetrafluoroethylene (PTFE) blended with additives that reduce ...

Federal-Mogul Deva GmbH

Inside diameter: 20 mm - 150 mm

Length: 0.5 in - 7 in

Material structure MOSTUF NW bearing has a twin layer structure. The inner layer is composed of special woven synthetic fiber and PTFE. The outer layer has high strength continuous glass fibers which are impregnated with ...

SOLTRI

... chemical resistance ■ Operating conditions Dry, maintenance-free ■ Availability Tubes, cylinderical bushes, plates, machined parts ■ Typical usage Iron and steel industry, agricultural equipment, pump bearing, ...

SOLTRI

CG72 Kamglide BUSH Specifications About KAMGLIDE KAMGLIDE composite bearings(Wear rings) are composite materials with thermosetting resin impregnated with fabric and have excellent strength and durability ...

SOLTRI

KAMGLIDE composite bearings(Wear rings) are composite materials with thermosetting resin impregnated with fabric and have excellent strength and durability compared with general thermoplastic materials. The characteristics ...

SOLTRI

... metal-PTFE composite specifically designed for play-free assemblies. Original patent by 3P consists of a metal mesh plain bearing sandwiched between one or two PTFE layers. This material offers the ...

Inside diameter: 0.38 in - 7 in

The Self-lubricating plain bearings is manufactured by RBC France. The product's performance values referred to in this section are based on dry application. When running in a fluid atmosphere, ...

... Pdyn,max 140 N/mm max. sliding speed v-dry 2.5 m/s max. PV factor-dry, continuous 1.8 N/mm2·m/s max. PV factor-dry, intermittent 3.5 N/mm2·m/s coefficient ...

IDEAL BEARING INC.

... v-oil lubricated 5.0 m/s max. sliding speed v-dry 2.5 m/s max. PV factor-dry 1.0 N/mm2·m/s max. PV factor- oil lubricated 10.0 N/mm2·m/s coefficient of friction f-dry ...

IDEAL BEARING INC.

... Pdyn,max 140 N/mm max. sliding speed v-dry 2.5 m/s max. PV factor-dry, continuous 1.8 N/mm2·m/s max. PV factor-dry, intermittent 3.5 N/mm2·m/s coefficient ...

IDEAL BEARING INC.

... v-oil lubricated 5.0 m/s max. sliding speed v-dry 2.5 m/s max. PV factor-dry 1.0 N/mm2·m/s max. PV factor- oil lubricated 10.0 N/mm2·m/s coefficient of friction f-dry ...

IDEAL BEARING INC.

... temperature Tmin -200 ℃ max. sliding speed v-dry 2.5 m/s coefficient of friction f-dry 0.02-0.25 coefficient of friction f-oil lubricated 0.02-0.12 shaft surface finish ...

IDEAL BEARING INC.

... temperature Tmin -200 ℃ max. sliding speed v-dry 2.5 m/s coefficient of friction f-dry 0.04-0.25 coefficient of friction f-oil lubricated 0.02-0.08 shaft surface finish ...

IDEAL BEARING INC.

... temperature Tmin -200 ℃ max. sliding speed v-dry 2.5 m/s coefficient of friction f-dry 0.04-0.25 coefficient of friction f-oil lubricated 0.02-0.08 shaft surface finish ...

IDEAL BEARING INC.

... v-oil lubricated 5.0 m/s max. sliding speed v-dry 2.5 m/s max. PV factor-dry 1.0 N/mm2·m/s max. PV factor- oil lubricated 10.0 N/mm2·m/s coefficient of friction f-dry ...

IDEAL BEARING INC.

... temperature Tmin -200 ℃ max. sliding speed v-dry 2.5 m/s coefficient of friction f-dry 0.02-0.25 coefficient of friction f-oil lubricated 0.02-0.12 shaft surface finish ...

IDEAL BEARING INC.

... load Pdyn,max 140 N/mm max. sliding speed v-dry 2.5 m/s max. PV factor-dry, continuous 1.8 N/mm*m/s max. PV factor-dry, intermittent 3.5 N/mm*m/s coefficient ...

IDEAL BEARING INC.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining