- Food industry >

- Other Food Machinery >

- Vacuum deaerator

Vacuum deaerators

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... -quality vacuum seals, provided with transparent methacrylate lids, that can be manually eliminated. They also have oil-bath rotating vane pumps for high vacuum instances, and one or two vacuum ...

n the NETZSCH Vacuum De-Aerator, micronized gases are removed from fluids with a wide range of viscosities. By means of the VTR Principle (vacuum – thin-film – rotary process), it is ...

... quality The DEA310 batch-deaerator can be applied as a standalone system or prior to the heat treatment of your product. The benefits of deaeration include reduced oxidation and improved product shelf life. As such, ...

... • Upper & Lower level controlled pneumatic acting valve for product inlet. • Automatic level control. • Vacuum pump. • Vacuum gauge and vacuum discharge valve. • Inverter speed controlled ...

... the vacuum vessel, using a product dispersion nozzle and vacuum stripping. The vacuum level is controlled to gently handle the product based on oxygen level desired, temperature, and ...

Microporous hollow fiber membrane in hydrodynamically optimized contactor designs that enable rapid and efficient gas transfer performance Capable of achieving very low dissolved gas levels down to 1 ppb O2 and 0.5 ppm CO2 at ...

3M Filtration & Separation

... deaerating system can help you with the precision deaeration of your beverage water. Using the two-stage, horizontal water deaerator this system provides you can also deaerate large quantities of water within the shortest ...

• Capacities up to 30.000 kg/hour* • From lab to industrial scale Functions: • vacuum deaeration Main applications: • mustard • paper coatings • honey • liquid detergents • carbomer suspensions • lubrication grease

The Derrick ACD-1500 Atmospheric/Centrifugal degasser is a unique in-tank alternative to the standard Derrick vacuum style Vacu-Flo 1200 degasser. The Derrick ACD-1500 degasser agitates ...

Derrick

ZCQ series Vacuum Degasser is a special-purpose device and a new type one for the treatment of gas in the drilling fluids. It can get rid of various gas of invasive drilling quickly. Vacuum ...

... and the mud for removal. The process is simple, yet very effective for well drilling fluids processing system. The vacuum degasser is used to remove the small entrained gas bubbles left in the mud ...

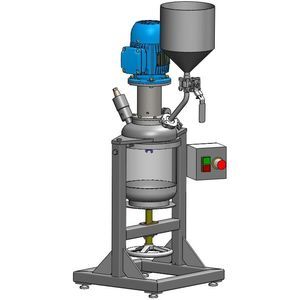

... reliable over time, they can be requested with different speeds, from 18 to 400 rpm. The external vacuum pump reaches a vacuum level of -0.95 Bar necessary to obtain a good degassing of the product. The ...

... with sliced apples (or other products), pull absolute vacuum on the tanks for a period of time (typically 10 – 30 minutes depending on apple variety / condition of apples) then prior to releasing vacuum ...

... fluid containing unwanted gases is subjected to negative pressures using a centrifugal pump with vacuum capability, bringing it to its boiling point. Under vacuum, the gases are separated from the boiling ...

... other products. Double deaeration technology by using deaeration double chamber on vacuum atmosphere. No consumption of CO2. Low consumption of water in the vacuum generator. Residual Oxygen <0.5 ...

The De-aerator type VD-05 is designed for laboratory batch production. The VD-05 is a highly efficient de-aerator. The product is automatically sucked into the vacuum vessel and has ...

... Performance Deaeration During continuous deaerating process of liquid to high viscosity products, a dynamic process Mechstar® Vacuum Deaerator offers a highly efficient, cost-effective solution. This ...

The Vacuum De-aeration Vessel or Vacuum Flash Vessel is used to receive the cooked product from the RotaTherm® Direct Steam Injection Cooker and 'flash' cool the product to the required filling temperature ...

... made up of a vacuum operating tank in which the product to be deaerated is sent. Thanks to a partial auto-evaporation, automatically controlled, the air contained in the products goes out. The plant is completed with ...

Characteristics of Vacuum Degasser by Kosun: 1. Self-priming device enables it to pump drilling fluids without centrifugal pump. 2. Corrosion is eliminated and cost of repairing as well as maintenance ...

... injectors or dry mechanical vacuum pumps to achieve deep vacuum with lowest energy consumption in shortest pump down time. Whereas steam ejector vacuum pumps offers a simple, almost ...

Thermal Deaerator /Steam Deaerator/Thermal Spraying Oxygen Eliminator/Deaerating Feed Water Heater/Demineralized Water Tank/Deaerator Storage Tank/Oxygen Extractor/Thermal Deaerator/Vacuum ...

... appropriate de-aeration system for the limit values and type of beverage to be produced with single stage or double stage vacuum de-aeration.

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining