- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

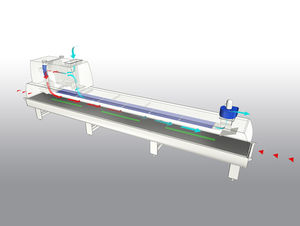

Curing oven UV-IchamberUVnitrogen

Add to favorites

Compare this product

Characteristics

- Function

- curing

- Configuration

- chamber

- Heat source

- UV

- Atmosphere

- nitrogen

Description

Inert Curing Oven

Ideal for a roller coating line, an oven designed to cure 100% UV lacquers in an inert atmosphere significantly reduces the need for photoinitiators, thereby reducing consumable costs and minimising the environmental impact of the curing process.

As the absence of oxygen enhances process efficiency, reducing the number of UV lamps needed to perform crosslinking, this means less energy is needed to activate the process and reduces overall energy consumption. Return on investment depends mostly on the reduced dependency on costly photoinitiators, but also comes from a more efficient process with lower energy costs.

UV-I solves the need to depend on photoinitiators to cure 100% UV lacquers by utilising an inert atmosphere in which oxygen is replaced by nitrogen. Oxygen is an obstacle which hinders the crosslinking process resulting in a need for photoinitiators. These are expensive and harmful to the environment, so the inert curing process cuts process-related costs and improves process sustainability. Less photoinitiator also means crosslinking is possible for even thinner coating layers than is customary today, and this means cutting lacquer costs as well.

Lower percentage of photoinitiator (between 40 and 70% less) required

Yellowing effect is significantly reduced as it is mainly due to the use of photoinitiators

Crosslinking performance improved, especially with low coating thicknesses

Eco-friendly process, reducing environmental impact and potential harm to operators

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.