Compounding extruder ZSK MEGAcompounderfor PPfor HDPEfor LDPE

Add to favorites

Compare this product

Characteristics

- Applications

- compounding

- Treated material

- for PP, for HDPE, for LDPE

- Number of screws

- twin-screw

- Output

Min.: 80 t/h

(48.9916 lb/s)Max.: 135 t/h

(82.6733 lb/s)- Screw diameter

Min.: 177 mm

(7 in)Max.: 420 mm

(16.5 in)- Maximum speed

320 rpm, 350 rpm, 400 rpm, 500 rpm, 550 rpm

(2,011 rad.min-1, 2,199 rad.min-1, 2,513 rad.min-1, 3,142 rad.min-1, 3,456 rad.min-1)- Torque

39,000 Nm, 107,000 Nm, 222,000 Nm, 311,000 Nm, 394,000 Nm

(28,765 ft.lb, 78,919 ft.lb, 163,739 ft.lb, 229,382 ft.lb, 290,599 ft.lb)- Power

4,500 kW, 11,200 kW, 18,600 kW, 22,800 kW, 26,400 kW

(6,118.3 hp, 15,227.76 hp, 25,288.95 hp, 30,999.36 hp, 35,894 hp)

Description

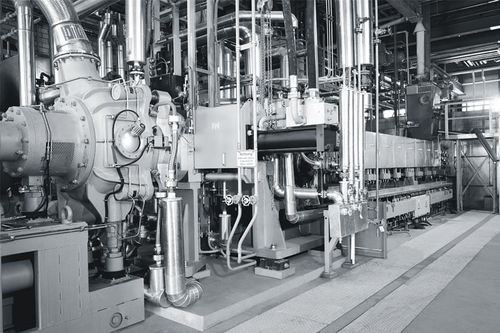

The twin screw extruder ZSK MEGAcompounder from Coperion is considered a milestone in the development of the high-performance compounding plants for the production of polyolefins. The extremely high productivity of the system is the result of more than 60 years of continuous research and development.

The ZSK MEGAcompounder series is ideally suitable for the economical processing of polyolefins. It constantly achieves maximum product quality especially in continuous processes with a high energy requirements. Its modular design principle allows optimal adaptation to every process. Whether it is a matter of continuously stabilizing, homogenizing and pelletizing LLDPE, HDPE or PP powder or concentrating a melt solution – with our many years of knowhow we configure the ZSK MEGAcompounder and the system auxiliary equipment to your individual process requirements. You achieve maximum throughput rates with the greatest possible cost effectiveness and the highest product quality with our systems.

The current series features a specific torque of 12.5 Nm/cm3. This brings polyolefin processing to the throughput rate of 135 t/h and beyond.

ZSK MEGAcompounder – High-capacity extruder for homogenization of polyolefins from the polymerization reactor

Catalogs

Compounding & Extrusion

14 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Pump

- Industrial pump

- Stationary pump

- Chemical pump

- Food product pump

- Extrusion line

- Thermoplastic extrusion line

- Process pump

- Cooling pump

- Pelletizer

- Gear pump

- Screw extruder

- High-performance pump

- Twin-screw screw extruder

- Rotor pelletizer

- PVC extrusion line

- Plastic pelletizer

- Waste granulator

- Compact pelletizer

- Compounding screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.