- Products

- Catalogs

- News & Trends

- Exhibitions

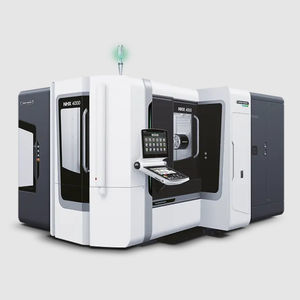

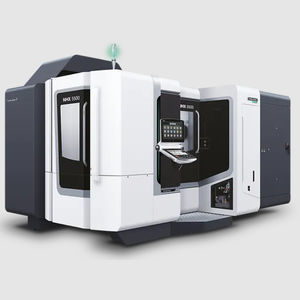

5-axis CNC milling center DMC 85 H monoBLOCKuniversalwith rotary tableHSK-A 100

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- universal

- Structure

- with rotary table

- Spindle mount

- HSK-A 100

- Other characteristics

- high-productivity

- X travel

850 mm

(33 in)- Y travel

1,150 mm

(45 in)- Z travel

900 mm

(35 in)- Rotational speed

800 rpm

(5,027 rad.min-1)- Workpiece max height

800 mm

(31 in)- Table load capacity

800 kg

(1,764 lb)- Tool weight (max)

30 kg

(66.1 lb)

Description

Ergonomic

Ergonomic cab for easy access to the work area and easy set-up of components

Fast double pallet changer for shortest non-productive times due to loading during machining

Thermosymmetrical design with extensive cooling measures for maximum long-term accuracy (up to 6 µm)

Maximum process reliability through horizontal machining for ideal chip and heat dissipation

Versatile

Extensive selection of flexible automation solutions thanks to standardized interface

Stiff monoBLOCK concept

monoBLOCK – Maximum stability from one casting

Highest availability due to reinforced mass production technology and optimum maintenance access

Proven division of round and linear axes for easy to understand 5-axis kinematics.

Clamping of the swivelling rotary table

AUTOMATION

Standard automation and customised solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customised automation solution for flexible manufacturing systems

VIDEO

Related Searches

- DMG MORI machining center

- DMG MORI vertical machining center

- DMG MORI lathe

- DMG MORI 3-axis machining center

- DMG MORI CNC lathe

- DMG MORI precision machining center

- DMG MORI 2-axis lathe

- DMG MORI CNC milling machine

- DMG MORI 5-axis machining center

- DMG MORI vertical CNC milling machine

- DMG MORI high-precision machining center

- DMG MORI 3-axis CNC milling machine

- DMG MORI rigid machining center

- DMG MORI high-precision lathe

- DMG MORI gantry machining center

- DMG MORI high-rigidity machining center

- Drilling machine

- Milling CNC machining center

- DMG MORI cutting machining center

- Column type CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.