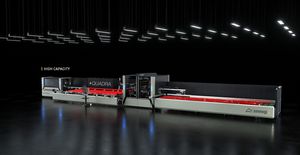

12-axis CNC machining center QUADRA L series13-axishorizontalfor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 12-axis, 13-axis

- Spindle orientation

- horizontal

- Machined material

- for aluminum

- Number of tool stations

- 32 outils

- Applications

- cutting, drilling, for profiles

- Other characteristics

- milling

- X travel

320 mm

(13 in)- Y travel

402 mm

(16 in)- Z travel

395 mm

(16 in)- Rotational speed

24,000 rpm

(150,796 rad.min-1)- Power

5.6 kW

(7.61 hp)

Description

CNC 13-axis machining centre, built for milling, drilling and cutting aluminium profiles and light alloys. Optionally it may be equipped with an end milling module. QUADRA L0 is an automatic magazine with a thrust-feed system for profiles up to 7,500 mm, complete with gripper movement to block the profile. Thanks to the movement of the gripper, the feeder returns to the start position allowing the loader to prepare the next profile at the same time. The milling module, the cutting module and the optional end milling module are located in the central area of the machine. There are 4 electrospindles installed on the CNC 4-axis milling module which allow working on the whole edge of the workpiece, whichever way it faces. The cutting module is equipped with a Ø 350 blade with CNC 3-axis horizontal movement. The optional end milling module operates on two CNC axes by means of a group of cutting units. QUADRA L0 also includes an automatic ejector to transfer the workpiece from the cutting unit to the unloading magazine. The unit is composed of a transverse belts magazine to unload machined workpieces of up to 4000 mm in length (optional 7500 mm). The machining unit is equipped with a sound-proof cabin in the central operating part, which, besides protecting the operator, reduces the environmental noise impact.

The core and value of the QUADRA L0 lie in its rotating base machining section, complete with 4 work units that are controlled and can be interpolated on 4 axes: X, Y, Z, A (360° slewing around the axis of the bar).

Catalogs

Related Searches

- CNC machining center

- Vertical CNC machining center

- Precision CNC machining center

- 5-axis CNC machining center

- High-precision CNC machining center

- Gantry CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Aluminum CNC machining center

- Horizontal CNC machining center

- Drilling CNC machining center

- Compact CNC machining center

- High-speed CNC machining center

- Heavy-duty CNC machining center

- Steel CNC machining center

- Modular CNC machining center

- 32 outils CNC machining center

- Copy router

- End milling machine

- Profile CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.