- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Oil cooler

- H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

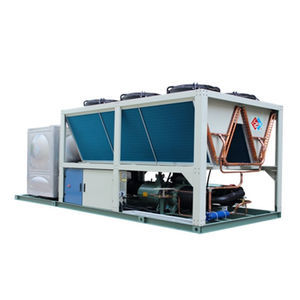

Air chiller WCI serieswateroilindustrial

Add to favorites

Compare this product

Characteristics

- Material

- air, water, oil

- Applications

- industrial, for the plastics industry, for refrigeration

- Other characteristics

- water-cooled, air-cooled, stainless steel, scroll compressor, outdoor, low-temperature, inverter, shell and tube, high-performance, adjustable, brazed plate, water-cooled, tubular, custom, reciprocating compressor, screw compressor, seawater resistant, air condenser, centrifugal compressor, gas cooler, single-stage, high-temperature, with heat exchanger, screw, IP54, high-speed, high-pressure, low-pressure, single-tank, air-cooled

- Power

Max.: 14.3 kW

Min.: 4.3 kW

- Maximum temperature

Max.: 55 °C

(131 °F)Min.: -25 °C

(-13 °F)- Flow rate

Max.: 238.8 l/min

(63.084 us gal/min)Min.: 48.7 l/min

(12.865 us gal/min)

Description

Industrial Integrated All In One Chillers for Plastic Industry

The plastic industry chiller unit is an integrated equipment designed for the industrial application. Integrated with the main components of chiller, chilled water tank, chilled water circulating water pump, process water pump, water piping system , all kinds of valves, and engineering control cabinets. Combine the project parts during the production line to save engineering labor cost.

Industrial Integrated All In One Chillers for Plastic Industry

Features of Industrial Integrated Chiller for Plastic Industry

1. Customization

H. Stars customizes the industrial integrated chiller unit based on various industries and projects and tailor-make integrated all in one industrial chiller to different clients.

2. Higher Energy Efficient

COP of 12℃ outlet water temperature higher (15~20%) than normal unit of 7℃ outlet water temperature, means energy-saving efficient.

3. Oversized Condenser and Evaporator

Oversized condensers not only make for a long lasting compressor, they

are also designed to operate in extreme conditions, i.e., above 45℃ and as low as -25℃, or at any temperature in between.

4. Heat Recovery

Supplying 55℃ free hot water, Heating Capacity approx. 1/3 of Cooling Capacity, increasing unit efficient about 5%.

5. Integrated System

Built in water tank and water pumps module set (with valves and strainer assemble in a module), no piping and wiring errors, simple installation, save time and labor cost.

6. Water Tank

For supplying a stable outlet water temperature, also supplying multiple outlet water temperature to different cooling requirements application.

VIDEO

Other H.Stars (Guangzhou) Refrigerating Equipment Group Ltd. products

INDUSTRIAL CHILLER

Related Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Air chiller

- Liquid/liquid heat exchanger

- Industrial chiller

- Compact chiller

- Tubular heat exchanger

- Stainless steel chiller

- Stainless steel heat exchanger

- Blast chiller for the food industry

- Gas/liquid heat exchanger unit

- Air-cooled recirculation chiller

- Oil chiller

- Laboratory recirculation chiller

- Industrial heat exchanger

- Compact heat exchanger unit

- Process water cooler

- Copper heat exchanger

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.