- Materials - Tools - Components

- Standard Mechanical Component

- Threaded insert

- KATO Fastening Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

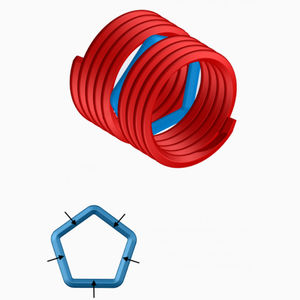

Threaded insert Nitronic 60®metalround

Add to favorites

Compare this product

Characteristics

- Type

- threaded

- Material

- metal

- Configuration

- round

Description

Inserts made from Nitronic 60 are specifically engineered to eliminate galling and fretting when used with stainless steel screws. The surface friction between the mating screw and the Nitronic 60 insert is superior to 304 Stainless Steel inserts due to the additions of silicon and manganese to the alloy which reduces wear and galling, thus particulate matter is eliminated completely or minimized. The inserts require no additional coatings or platings, making them ideal for use in a vacuum as there is no out gassing, and they are not limited by the lower temperature capabilities of some platings and coatings, e.g. cadmium and dry film lubricant. The inserts are non-magnetic (< 1.0 G/O), have good corrosion resistance, a tensile strength of approximately 200,000 PSI, a hardness of Rc 43-50 and can be used in temperatures up to 500° F. Typical applications include semiconductor, aerospace industries, or when requirements indicate the use of 300 series Stainless Steel male fasteners. The material is metal alloy number UNS S21800.

Related Searches

- Hinge

- Metal hinge

- Threaded insert

- Metal insert

- Threaded plug

- Round insert

- Stainless steel lift-off hinge

- Stainless steel insert

- Plastic hinge

- Hexagonal plug

- Aluminum insert

- Friction hinge

- Spring hinge

- Small hinge

- Stainless steel fastener

- Plastic fastener

- Constant-torque hinge

- Locking insert

- Asymmetrical hinge

- Nylon fastener

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.