- Production Machines

- Other Manufacturing Equipment

- NETZSCH Grinding & Dispersing

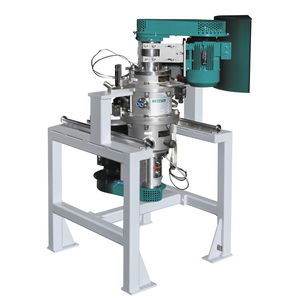

Graphite rounding unit GyRho

Add to favorites

Compare this product

Description

The graphite rounding process developed by NETZSCH overcomes disadvantages of the previously widespread used process requiring more than 20 classifier mills installed in rows: In a first step, the flock graphite is pre-ground to the optimum initial particle size for spheroidization in a classifier mill or fluidized bed jet mill.

The actual particle rounding process takes place directly downstream in the newly designed NETZSCH GyRho Rounding Unit (Fig. 2) which is available in various construction sizes and can be specially designed to suit the necessary output quantity. For larger throughput volumes two (or more) machines can be operated simultaneously and can replace the train of 20 machines or more as mentioned above.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Other NETZSCH Grinding & Dispersing products

Dry Grinding

Related Searches

- NETZSCH mill

- NETZSCH horizontal mill

- NETZSCH vertical mill

- NETZSCH food mill

- NETZSCH rotor mill

- NETZSCH impact mill

- Knife chopper

- Plastic pulverizer

- Mill for the pharmaceutical industry

- NETZSCH laboratory mill

- NETZSCH compact mill

- Grinding mill for the food industry

- Stainless steel grinding mill

- NETZSCH powder mill

- Rotary drum grinding mill

- NETZSCH dry milling mill

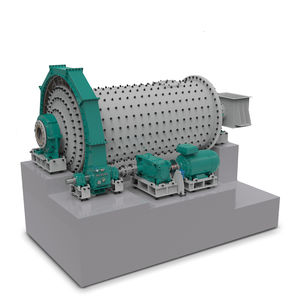

- Ball grinding mill

- High-speed pulverizer

- Metal mill

- High-performance grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.