- Production Machines

- Other Manufacturing Equipment

- Knife mill

- NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

Knife mill LM Serieshorizontalfor PET bottlesfor cables

Add to favorites

Compare this product

Characteristics

- Technology

- knife

- Orientation

- horizontal

- Product applications

- for spices, for herbs, for cables, straw, for organic waste, mineral wool, for plastics, for rubber, for PET bottles, copper

- Power supply

- 380V three-phase, 400V three-phase

- Other characteristics

- dry milling, wet grinding, universal, powerful, edge trim, centralized

- Sector

- for recycling, for the chemical industry, for the plastics industry, for injection molding, for pipes and profiles, for thermoforming lines, for blow molding

- Output

Min.: 50 kg/h

(110 lb/h)Max.: 1,500 kg/h

(3,307 lb/h)

Description

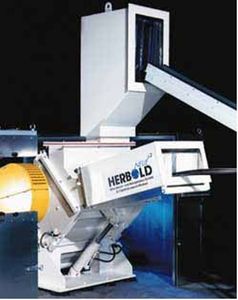

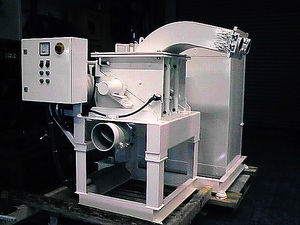

LM series granulators are equipped with rotor and stator knives in a crossed manner for scissor like exact cutting action. This machine helps in finer and identical cutting and keeps the heat formation stable. This type of cutting also reduces the noise and consumes less energy. The knives are very sharp and straight and don't need any sharpening process. The gaps between the rotor blade perimeter and screen is maintained by changing the knife size using some tools. This helps in reducing friction and thermal stress of material. Changing of knives can be done 60% faster and in safer way by adjusting it outside granulator. The rotor is placed in a steel container which protects it from heavy shock loads.

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

Other NEUE HERBOLD Maschinen-u. Anlagenbau GmbH products

Granulators

Related Searches

- NEUE HERBOLD mill

- Screening unit

- Bulk material screening unit

- Horizontal grinding mill

- Vertical grinding mill

- Food lump breaker

- NEUE HERBOLD rotor mill

- Vibrating sieving machine

- Impact grinding mill

- Waste lump breaker

- NEUE HERBOLD knife mill

- NEUE HERBOLD plastic mill

- Recycling screening unit

- Mill for the pharmaceutical industry

- Mineral mill

- Hammer grinding mill

- NEUE HERBOLD recycling mill

- Powder grinding mill

- NEUE HERBOLD dry milling mill

- High-speed pulverizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.