- Products

- Catalogs

- News & Trends

- Exhibitions

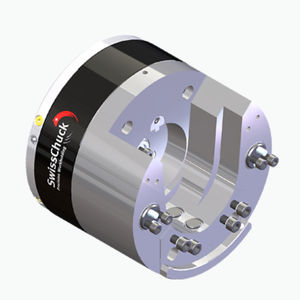

Grinding workpiece clamping chuck KCHPcentricalprecisioncylindrical

Add to favorites

Compare this product

Characteristics

- Clamping method

- centrical

- Application

- grinding

- Other characteristics

- precision, cylindrical, radial, with coolant, pneumatic

- Number of jaws

- 3-jaw

- Rotational speed

1,500 rpm, 2,000 rpm, 2,250 rpm, 2,500 rpm, 3,000 rpm

(9,425 rad.min-1, 12,566 rad.min-1, 14,137 rad.min-1, 15,708 rad.min-1, 18,850 rad.min-1)

Description

The KCHP/VKCHP precision power chucks have been specifically designed for cylindrical grinding machines. The chucks are hermetically sealed against contamination and are oil-filled for permanent lubrication to ensure a flawless long-term operation. These design features render the chucks nearly maintenance-free. All the precision power chucks of the generation KCHP/VKCHP now also feature volume compensation to prevent unwanted oil loss or grinding fluid ingress.

OD and ID clamping

Large central bore (through hole)

Power chuck (KCHP) for actuation through a pneumatic cylinder

Power chuck (VKCHP) pneumatically actuated on the front-end

Ideal chuck for all cylindrical grinding machines

High precision ≤ 0.002 mm

Low on maintenance

Hermetically sealed and lubricated

Suitable for grinding machines

Lightweight design

Precision interfaces between the base and top jaws

Do not require regrinding of clamping position after a change of jaws

Possible to interchange jaws between chucks of identical design

Standard accessories are readily available

Catalogs

PRECISION POWER CHUCK

12 Pages

PRECISION POWER CHUCK KCHP/VKCHP

12 Pages

Related Searches

- SwissChuck chuck

- Drilling chuck

- Collet chuck

- Magnetic chuck

- High-precision chuck

- Power chuck

- 3-jaw turning chuck

- SwissChuck workpiece clamping chuck

- Lathe turning chuck

- High-speed chuck

- Machining turning chuck

- Permanent magnet magnetic chuck

- Precision turning chuck

- Machining collet chuck

- Through-hole turning chuck

- Radial chuck

- Manual tightening chuck

- Mandrel

- Self-centering turning chuck

- SwissChuck 3-jaw workpiece clamping chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.