- Power Transmission - Mechanical components >

- Mechanical Transmission >

- Transmission belt

Transmission belts

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Length: 100, 200, 150 m

Width: 45 mm

Temperature: -25 °C - 80 °C

MEGALINEAR LIVE ROLLER END-USER 45MM THE NEW MEGADYNE PERFORMANCE BELT DESIGNED TO MEET THE NEEDS OF LIVE ROLLERS IN AUTOMATED WAREHOUSE SYSTEMS. It is manufactured from polyurethane 85 ShA, in standard yellow with ...

MEGADYNE

... sources. That means this “eco-friendly” belt solution can support companies that have embraced sustainability as part of their policy and are taking care of the environment. MEGALINEAR Biobased timing ...

MEGADYNE

Thickness: 2.4 mm - 13.7 mm

Pitch: 8, 5, 3, 14 mm

Temperature: -25 °C - 80 °C

... teeth surface. Timing belts Rubber endless MEGASYNC™ RPP and RPP DD MECHANICAL AND CHEMICAL PROPERTIES less noise less pre-tension higher transmittable torques improved resistance to tooth jump and ...

MEGADYNE

Width: 28 in

... option to use a narrow belt No lubrication and no re-tensioning needed, eliminating maintenance costs throughout the life of the belt Improves ergonomics — less weight reduces fatigue ...

Gates Europe

Temperature: -40 °C - 130 °C

... material throughput, and expectations for uptime and platform reliability. The needs of belt driven power transmission technologies to enable uptime has only become more prominent ...

Gates Europe

Length: 480 mm - 1,200 mm

Width: 48.5 mm - 102 mm

Thickness: 2.2 mm - 10 mm

... APPLICATION ADVANTAGES YOU CAN COUNT ON. Linear Timing Belts provide the greatest degree of flexibility for both synchronous conveying and linear positioning applications. Gates TPU manufactures linear ...

Gates Europe

Width: 10 mm - 38 mm

Thickness: 6 mm - 23 mm

Temperature: -35 °C - 65 °C

SKF Wrapped Classical Belts have been developed to handle the majority of industrial applications and some agricultural machines. They can run on ISO wedge as well as on classical V-belt pulleys. Suitable ...

SKF Maintenance,Lubrication and Power Transmission

Width: 9.7 mm - 25 mm

Thickness: 8 mm - 23 mm

Temperature: -40 °C - 130 °C

SKF Wedge & Wrapped Narrow Wedge Belts have been developed to handle the majority of industrial applications running on ISO wedge as well as on classical V-belt pulleys. Very high ...

SKF Maintenance,Lubrication and Power Transmission

Length: 0 mm - 3,500 mm

Width: 10, 13, 17, 22 mm

Thickness: 6, 8, 11, 14 mm

SKF Cogged Raw Edge Wedge & Classical Belts have been developed to handle the majority of industrial applications running on ISO wedge as well as on classical V-belt pulleys. • Very high flexibility • ...

SKF Maintenance,Lubrication and Power Transmission

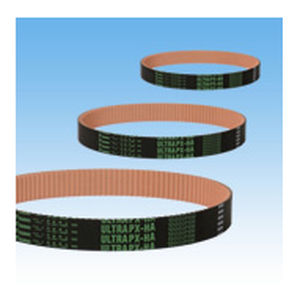

Width: 6 mm - 120 mm

Pitch: 5, 8, 14, 3 mm

Temperature: -15 °C - 60 °C

HC Type Ultra PX Belts enable high load transmission, long life, and compactness thanks to its high strength material and PX belt tooth contour. Next-generation timing belt ...

Tsubakimoto Chain

Width: 10 mm - 120 mm

Pitch: 8, 14, 5 mm

Temperature: 0 °C - 60 °C

... . This belt is based on the high-performance "Ultra PX belt HC type", with added oil and water resistance, and has the same transmission capacity as HC type. *The Oil Proof Type Belt ...

Tsubakimoto Chain

Width: 6 mm - 120 mm

Pitch: 5, 8, 14, 3 mm

Temperature: -15 °C - 60 °C

HY Type Ultra PX Belts use a hybrid core of carbon and glass for dramatically increased strength and durability. Tsubaki pursued maximum performance to bring even higher load transmission and longer ...

Tsubakimoto Chain

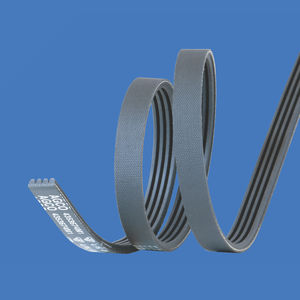

Poly V belt transmits the torque and the power by contact of the belt rib flanks and the pulley grooves. The Hutchinson Poly V is a molded belt, its monobloc design guarantees: Compactness High ...

HUTCHINSON Belt Drive Systems

... high quality power transmission Reduced costs The Flexonic® belt is a molded belt and has been designed with a larger contact surface area than V belts or flat belts ...

HUTCHINSON Belt Drive Systems

This Flexonic® NANO Elastic Belt is specially designed for small household appliances, hand tools and micro-mechanisms where synchronism is not necessary. PERFORMANCE Lower hub loads Silent drive Easy to fit

HUTCHINSON Belt Drive Systems

Thickness: 3, 4, 5, 6 mm

... gentle treatment of goods Polyamide folder-gluer belts The design and production of Habasit's polyamide folder-gluer belts is based on many years of experience with polyamide products. These belts ...

Habasit

Width: 4.76 mm - 76.2 mm

Thickness: 0.5 in - 0.79 in

Variable speed cog-belts are designed for use with industrial variable speed pulleys to gain a wide range of driven speeds. Timken Belts is a leader in variable speed belt ...

Timken Belts

Length: 677 mm - 2,217 mm

Width: 11 mm - 35 mm

... Serpentine belt drive systems, collaborates with OE manufacturers globally to continually evolve the performance and durability of belt drives. Certain vehicle engines require specific belt ...

GATES

Width: 10 mm - 25.4 mm

Thickness: 6 mm - 23 mm

Temperature: -25 °C - 100 °C

... : Higher power transmission capacity than wrapped Belts Special cog design for enhanced flexibility and heat dissipation rate Suitable for drives using smaller diameter pulleys and high RPM Anti-static, ...

PIX Transmissions Limited

Length: 546 mm - 5,000 mm

Width: 9.7 mm - 15.8 mm

Thickness: 14, 13.5, 18, 10, 8 mm

... - up to 50% more than standard Belts Special cog design facilitates enhanced flexibility and quicker heat dissipation High transmission efficiency up to 98%, providing optimum output Maintenance-free ...

PIX Transmissions Limited

Length: 700 mm - 5,000 mm

Width: 9.7 mm - 22 mm

Thickness: 8, 10, 14, 18 mm

... in minimal service costs. - Exceptionally high power rating over standard Belts. - Special Belt surface design for superior flexibility and abrasion resistance. - High transmission efficiency ...

PIX Transmissions Limited

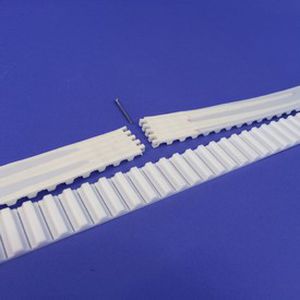

Toothed belts T profile Material: Polyurethane (PU) with steel cord reinforcement. Note: Endless toothed belt with trapezoidal profile to DIN 7721 T1 with metric pitch. Ideal for drives with high belt ...

Toothed belt profile HTD 5M Material: Belt back and belt teeth CR. Tension cords Glascord. Tooth covering mesh polyamide. Note: Endless toothed belts with an arched ...

V-belts DIN 2215 Description Material: Neoprene with polyester tensile cord. Note: Endless V-belt acc. to DIN 2215 (classic V-belt). Electrically conductive acc. to ISO 1813. ...

... cross section is increased (when compared to the standard belt) and this results in a lower belt elongation and more precise positioning accuracy. • HPFE high resistance and flexibility: this kind of ...

Elatech S.r.l.

Length: 900 mm - 9,000 mm

Temperature: -25 °C - 80 °C

... ELA-flexSD® belts are manufactured with high tension strength steel tension cords and with high wear, abrasion and tear resistant polyurethane. Having no splice or welding, the belts have no weak cross ...

Elatech S.r.l.

Temperature: -10 °C - 80 °C

Elatech iSync® timing belts are innovative high performance belts for power transmission made with polyurethane resin body and tension cords in steel or aramid fiber. ...

Elatech S.r.l.

... Double-sided belts have teeth equally constructed on each side of the belt, which enables them to mesh with toothed pulleys on both the inside and outside. The construction of the belts ...

Double-sided belts have teeth equally constructed on each side of the belt, which enables them to mesh with toothed pulleys on both the inside and outside. The construction of the belts ...

Siegling Extremultus machine tapes are vital components of machinery in many industrial applications. Tension members made of polyester/aramide fabric, polyamide sheet or elastic urethane make them ideal for a range of different areas. Siegling ...

Forbo Siegling GmbH

Compared with other power-transmission products, Siegling Extremultus power-transmission belts stand apart because they offer a better level of efficiency (≥ 98 %), high level of synchronization ...

Forbo Siegling GmbH

... optimize quality assurance (contrast to food) – elastic and thus excellent for short center distances, belt scales and are suitable as spreading belts – easy to clean – chemically resistant – available ...

Forbo Siegling GmbH

... consumer applications and much more. The Velcro (hook and loop) fastener strips are available on a 25 m roll and are cut as required. Particular benefits of the KB-fix Velcro strip are: Very simple ...

MURRPLASTIK SYSTEMTECHNIK

Wrapped heavy-duty V-belts with reinforced tensile member and advanced compound for safely transmitting more power, DIN 7753. Temperature resistant between -30°C and +80°C Antistatic in accordance with ISO 1813 ...

Continental Industry Contitech

Width: 15 mm

DEREMAUX

DEREMAUX

DEREMAUX

Length: 378 mm - 15,320 mm

Width: 10 mm - 38 mm

Thickness: 6 mm - 23 mm

V-belts, also known as Z, A, B and C belts, are designated by their width. The letters (Z, A, B, C) define the width of the belt, while the accompanying number indicates the length and ...

CMW

Length: 512 mm - 5,600 mm

Width: 10, 13, 16, 22 mm

Thickness: 8, 10, 13, 18 mm

XP belts are the toothed versions of narrow belts, offering increased flexibility. Unlike other belts, the teeth of the XP belt are not used to drive ...

CMW

Length: 111 mm - 6,880 mm

Width: 6 mm - 500 mm

Pitch: 3, 5, 8, 14 mm

HTD synchronous belts have been recognized for many years for their outstanding performance in a variety of applications. Compared with conventional inch V-belts, they offer considerably higher power ...

CMW

Pitch: 14, 8 mm

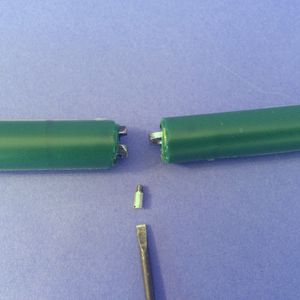

... provide the only existing transmission belt with mechanical assembly. The only existing transmission belt with mechanical assembly, a unique solution on the market. It ...

TANALS_ERO Joint®

... above 10 mm with reinforcement Steel, Kevlar or Stainless steel. The mechanical resistance of split belts ERO Joint® HP is equivalent to welded belts. Metal components are in stainless steel. No minimum ...

TANALS_ERO Joint®

... currently improved. Polyurethane round belts ERO Joint® are suitable for power transmission or for transport. In all cases, the mechanical assemblies ERO Joint® are linked to a traction cord embedded ...

TANALS_ERO Joint®

Banded V-Belts group multiple v-belts by a common backing and are available in A(1/2") groove, B(5/8") groove, C(7/8") groove and D(1-1/4") Groove. This increases the durability of the v-belt ...

Tempo International

Width: 13, 17, 22 mm

Thickness: 10, 13, 17 mm

... Sided Belts Features: Are used to transmit power on both sides of the belt. Build with special tension cords to meet multiple bend and dual power requirements. Oil and heat resistanttanged. Are used ...

Tempo International

Link V-belts are made from interconnected links that can be customized to any length without using tools. They are typically used to replace standard V-belts, eliminating the need to stock different lengths ...

Tempo International

Rear Wheel Drive Timing Belts ・Belt for rear-wheel drive of motorcycles. ・High transmission performance and excellent quietness even in harsh environments where dust ...

MITSUBOSHI EUROPE

Length: 1,000 mm

MAXSTAR POWER EP-X is developed to reduce downtime of retensioning by tension stability improvement, and demonstrates its capability when used under high loads such as HVAC, compressor, construction equipment, and industrial pump. Characteristics ...

MITSUBOSHI EUROPE

・Synchronous transmission belts with high transmission efficiency used in cam drives for automobile engines. ・It has excellent durability in the high-temperature environment characteristic ...

MITSUBOSHI EUROPE

STANDARD FOAM BELT Foam belt Categories: Glass factory, Inspection machines, Spacers / Conveyors DESCRIPTION Product description Black foam, grey foam, or spongy foam Different length, thickness, ...

Grey Toothed Foam U profile grey foam Toothed foam with felt Linatex coating Foam + fabric

V-belt PU75A red smooth (also available as notched version) approx. 80° Shore A Recommended pretension 4...8% available profile dimensions (mm): 6x4 (Y), 8x5 (M), 10x6 (Z), 13x8 (A), 17x11 (B), 22x14 (C), 32x20 (D)

BEHA Innovation GmbH - BEHAbelt

V-belt PU75A sky blue smooth Hardness: approx. 80°Shore A Recommended pretension: 4...8% FDA/EC/USDA conformity Hydrolysis resistant available profile dimensions (mm): 6x4 (Y), 8x5 (M), 10x6 (Z), 13x8 (A), 17x11 (B)

BEHA Innovation GmbH - BEHAbelt

V-belt PU85A sapphire blue smooth (also available as notched version) approx. 88° Shore A Recommended pretension 4...8% FDA/EC/USDA conformity

BEHA Innovation GmbH - BEHAbelt

... mileages at low stress and for plastic belts. The springs are made of a high-quality special wire, which achieves an up to ten times longer service life than conventional spring wires. Steel belt motor ...

Length: 100 cm

Width: 9.7, 12.7, 16.3, 22 mm

Temperature: -55 °C - 70 °C

NARROW V-BELTS CONTI®V DIN 7753 CONTI®V WRAPPED V-BELTS FOR DEMANDING DRIVES IN ALL SECTORS OF MACHINE ENGINEERING, DIN 7753 Properties › Matched set L=L (from 1000 mm) › Electrically ...

BEA Ingranaggi

Your suggestions for improvement:

A transmission belt is a loop of flexible material used to link two or more rotating shafts. It can transmit power or motion without losing synchronization. It transfers continuous rotational motion between a drive shaft and a driven shaft separated by a fixed distance.

ApplicationsThese belts are best known from their presence in automobile engines, which often have a toothed timing belt and a ribbed accessory belt driving the alternator, power steering pump, water pump, etc. Similar belts may be found on motorcycles, bicycles and in numerous industrial settings requiring power or motion transfer, notably on conveyors.

TechnologiesEach of the many different types of transmission belt has its particular characteristics. These include flat, round, trapezoidal, ribbed and toothed belts.

How to chooseChoice will depend on:

- Power to be transmitted

- Speed of drive and driven shafts

- Shaft separation

- Space constraints

- General conditions of use (vibration, surge, shock, temperature, humidity, dirt, etc.).

- Silent transmission at high speed

- Spans large gaps

- Simple and economical

- Dampens shocks and vibrations

- Relatively short life

- Low torque capability

- Requires proper tensioning

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining