- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Elastomer coupling LF seriestorsionally flexiblelocking devicefor pumps

Add to favorites

Compare this product

Characteristics

- Type

- elastomer, torsionally flexible, locking device

- Product applications

- for pumps, transmission, for presses, for paper machines, for chemical applications, for lifting equipment, turbine, for railway vehicles, for shafts, for servo motors, gas, for hoisting machinery, for blowers, for the packaging industry, for the textile industry, for marine applications, for mechanical power transmission, for electric motors, flange, for the aerospace industry, for machine tools, for stepper motors, gearbox, for compressors, for conveyors, for the food industry, for mixers, for agitators, for the cement industry, for wind turbine, for printing machines, for railway applications, machines, for gears, generator, for diesel engines, industrial

- Other characteristics

- torque, compact, backlash-free, for splined hubs, high-speed, low noise and vibration, disassemblable, maintenance-free, with high torsional flexibility, flywheel, non-lubricated, shaft-hub, misalignment correction, with clamp, variable-speed, compensating, high-performance, large-size, heavy-duty, large, close-coupled, high load capacity, anti-vibration

- Installation system

- flange, shaft sleeve

- Torque

Max.: 12,500 Nm

(9,219.5269 ft.lb)Min.: 0 Nm

(0 ft.lb)5,000 Nm

(3,687.8107 ft.lb)- Rotational speed

Max.: 10,000 rpm

(62,831.85 rad.min-1)Min.: 2,500 rpm

(15,707.96 rad.min-1)

Description

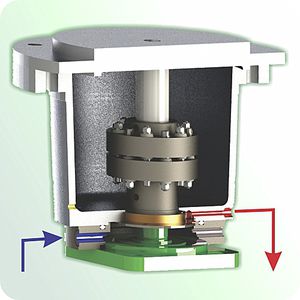

This range of torsional couplings solve torsional vibration problems typical of those found in diesel engine applications. The torsional coupling dampens torsional vibrations and tunes the system to have critical speeds outside the operating range.

jbj Techniques Ltd can analyse the application and determine the exact torsional coupling needed for almost any application.

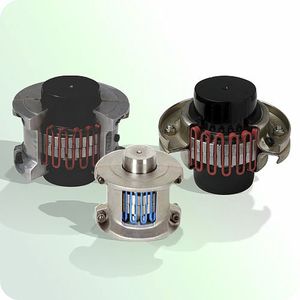

LF torsional couplings

Substantial shock, vibration and misalignment capabilities, maintenance free, fail-safe operation.

For applications with diesel, gasoline or natural gas engines which drive one or more flange-mounted hydraulic pumps.

» Solve torsional vibration problems within Diesel engine applications.

» Torsionally flexible or rigid dependant on application.

» Low weight, low moment of inertia.

» Small overall length aids equipment design.

» Enables disassembly without moving driver/driven equipment.

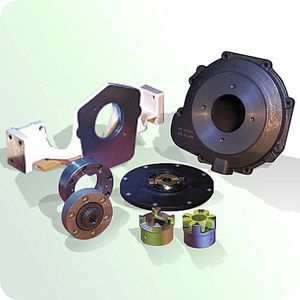

» Flanged versions suit SAE standard and non-standard arrangements.

» LM series design protects driver/driven equipment under stall condition

Catalogs

Other jbj Techniques Limited products

bellhousings & couplings for mechanical power transmission

Related Searches

- Gearbox

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Flexible shaft coupling

- Gear train gearbox

- Shafts coupling

- Friction brake

- Solid-shaft gearbox

- Transmission gearbox

- Flange shaft coupling

- Hollow-shaft gearbox

- Single-stage gearbox

- Multi-stage gearbox

- High-performance gearbox

- High-efficiency gearbox

- Spring brake

- Two-stage gearbox

- Disc brake

- Torque shaft coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.