- Industrial machines and equipment >

- Mixing and Dosing >

- Batch blender for the plastics industry

Batch blenders for the plastics industry

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... materials such as epoxies, polyurethanes and silicones. The material is supplied from pressure vessels. Special configurations to process high viscosity media are also available. Features and Benefits Variable mixing ...

... the outlet of which a disposable plastic mixer is mounted. The use of a hose package with a decentralized mixing system is also possible. Just a suitable material supply and metering computer is required. Industries Where ...

Flow rate: 80 kg/h - 1,770 kg/h

GRAVIMAX blender models Series 1, 3, 7, 9, and 18/27 for batch sizes from 1 to 27 kg (2.2 to 60 lbs.) Advantages of GRAVIMAX Blenders Simple operation Highly precise metering ...

gravimetric mixer-dispenserGRAVICOLOR

Flow rate: 0 kg/h - 2,200 kg/h

... throughputs up to 2200 kg/h. Independent of recipes, materials, or the operational environment, IntelliBlend analyses all process data achieving the best possible operating point at any time through continuous self-optimisation. ...

motan gmbh

The gravimetric batch dosing and mixing unit GRAVICOLOR 110 med has been specially developed to meet the needs of plastics processors in the medical and pharmaceutical industries ...

motan gmbh

... design and excellent engineering guarantee optimum performance, flexibility, and reliability of the units. This gravimetric batch dosing and mixing unit can be used for injection moulding, blow moulding and extrusion ...

motan gmbh

Flow rate: 50 kg/h

OPTI-MIX 50 Batch Blenders can accommodate up to four material components while providing throughput rates up to 50 kg/hr (110lb/hr). OPTI-MIX 50 utilizes TSM slide valve design and patented reverse-flight ...

TSM Control Systems

Flow rate: 350 kg/h

The OPTIMIX-300 Series Batch Blender can accommodate up to four material components while providing throughput rates up to 350 kg/hr. The range of blenders utilises the patented TSM slide ...

TSM Control Systems

Flow rate: 650 kg/h

The OPTIMIX-600 Series Batch Blender can accommodate up to four material components while providing throughput rates up to 650 kg/hr. The range of blenders utilises the patented TSM slide ...

TSM Control Systems

... depending on mixing ratio, material and dispenser combination) ▪ Application-specific design must be carried out by ViscoTec process experts

... segments with pressure sensors for online process monitoring, sensors are integrated dead space free - easy assembly / disassembly of the components by newly developed pump connection principle - accurate dosing process ...

... dosing and mixing system was specially developed for applications in the aerospace industry. Application examples: - Sealing applications in the aerospace industry - Application of compressible ...

... MAXIMATOR Gasdosing Station is designed for the high-pressure dosing of gas for the physical foaming of plastics. The physical foaming is applied in the process variants extrusion foaming, polyurethane ...

... Cost efficient dosing system for two part materials The LiquidShot 3 is the first choice for all applications focused in electronic potting and encapsulation. Proven piston pump technology allows for consistent, small ...

Accuracy: 0.02 %

Flow rate: 480 kg/h

Power: 150 W

... pre-mixed material batch. The gravimetric dosing units, equipped with our unique Balance technology, deliver a remarkable 3x improvement in shot-to-shot accuracy compared to our MBS Blender. The MHBS ...

Accuracy: 0.02 %

Flow rate: 1,600 kg/h

Power: 400 W

... shot-to-shot accuracy compared to our MBS Blender. The MHBS Hybrid Blender offers plastic processors complete control over their production processes and consistently proves its value ...

Accuracy: 1 %

Flow rate: 1 kg/min

Power: 5 kW

... BASIC TECHNICAL PARAMETERS Metering type Continuous metering, low pressure Mixing type Dynamic mixing with adjustable mixer speed Number of metered components 3 components Output From 500 ml/min to 2.000 ml/min, ...

OSV

Accuracy: 1 %

Flow rate: 10 kg/min

Power: 15 kW

... easy change of hardness of parts in a wide range from 45o Shore A to 70o Shore D The OSV M MDI casting machines allow to process three-component polyurethane systems based on MDI and easily change the hardness of parts ...

OSV

Accuracy: 2 %

Flow rate: 2 kg/min

Power: 5 kW

Output of mixing and dispensing machinery OSV of S Series, as a rule, does not exceed 1 liter of mixture per minute. But in this, perhaps, is their main advantage over units of larger output. There are a number of technological processes, ...

OSV

... extruders are used, the SAVEOMAT COEX application ensures a stable production process and a constant flow of material. Based on the recorded measurement data, the corresponding process parameters are ...

Accuracy: 1 % - 1 %

Flow rate: max 30.0 kg/min

FLEXjet+ Dispensing System for small to medioum viscous application. Technical Information Solvent based / water based / UV flexo und gravure inksInk dispenser The FLEXjet ink dispenser saves print shops resources, speeds up job preparation ...

... bin, which contains a very accurate weighing system. When the weighing is done, the complete batch will fall into the mixing chamber and the horizontal mixer will ensure a uniform blend. A level sensor ...

Ferlin Plastics Automation

... machines. Since then we have listened a lot to our customers. Due to the many good ideas, our batch blender has become the most user-friendly batch blender on the market. Our ...

Ferlin Plastics Automation

... machines. Since then we have listened a lot to our customers. Due to the many good ideas, our batch blender has become the most user-friendly batch blender on the market. Our ...

Ferlin Plastics Automation

Accuracy: 0.5 %

Flow rate: 79 kg/h - 5,443 kg/h

... with full color graphics allows quick and easy setup of blender setpoints. All setpoints are displayed simultaneously. Enter the percentages of the blend on the touchscreen display and the blender does ...

Conair

... to ensure high accuracy, versatility and accuracy in extrusion processes, enhancing the advantages of both the gravimetric batch technology and the loss-in-weight systems. Quantum E allows a versatility of use that ...

Piovan

• Polyol and blowing agent metering devices • Static mixer for inline blending • Independent control cabinet with touch screen operator panel • Inverter for the Polyol output control • Closed loop ...

Accuracy: 0.02 %

Compact batch blenders for feeding up to 8 ingredients in your plastics compounding process Coperion K-Tron Gravimetric Batch Blenders ...

... is mainly used in plastic injection molding, extrusion or hollow molding, etc. 3.It adopts weight sensor and PLC controller to control precise flow of per metering value. 4.It can accurately control every ingredient ...

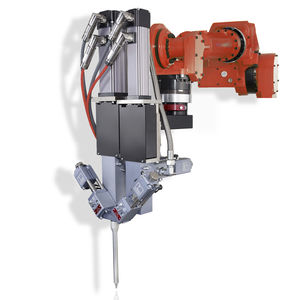

... 402/403 precisely processes liquid, medium to high viscose media such as polyurethane, silicones, epoxy resins and other polymer reaction substances.

HENKEL SONDERHOFF

BlendSave is a central Multi-Channel Gravimetric Batch Blender that provides optimal factory management of multi-ingredients and multi-process machine combinations for all plastic manufacturing ...

Flow rate: 227, 410, 1,135, 1,815, 2,725 kg/h

Power: 0.1, 0.3, 0.8 kW

The BD Series batch weigh blenders are setting new industry standards for accuracy and homogeneous blend quality with quick-acting diamond slide gates, unique mix chambers, and an easy ...

AEC, Inc. - ACS Group

... weigh-bin, which is supported by an accurate weighing system. After weighing out the complete batch is dischar- ged into the mixing chamber and the horizontal mixer provides a consistent blend. A level ...

Labotek

... MicroBlender™, the smallest weigh scale blender in the world, features the latest technology in gravimetric blending. The MicroBlender™ makes the benefits of gravimetric blending accessible and affordable to plastics ...

Maguire Products Inc.

... MIXACO laboratory mixer is an optimum solution for the development of new recipes that need to be transferred rapidly to industrial manufacturing. Simple upscaling of mixing parameters enables conversion ...

MIXACO Maschinenbau

For the treatment of high viscosity raw material systems that need to be heated to 50-130 °C -individual temperature control of polyol and isocyanate. -each component tank and metering system are installed in the incubator. -material ...

... applications where precision and control are essential. This machine can be modified / customized according to your needs to process dielectric resins, Polyurethane, Epoxy or Silicone and can to be present throughout ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining