- Industrial machines and equipment >

- Surface Treatment Equipment >

- Clean-in-place unit for the food industry

Clean-in-place units for the food industry

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

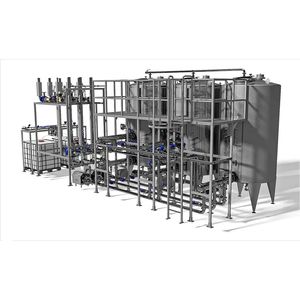

Cleaning-in-place (CIP) systems circulate cleaning liquids in a cleaning circuit through machines, processing lines and other equipment. CIP units for efficient cleaning of pipeline systems, tanks and processing plants with a choice ...

CIP system working principle: Is to control the opening and closing of the steam valve by measuring the temperature sensor; to control the opening and closing of the water valve by measuring the level of the liquid through the pressure ...

We design and manufacture CIP and Mini CIP for tankers or food plants washing. These units are available in manual, semiautomatic and automatic versions. FEATURES: - Mounted on a stainless steel base; - Centrifugal pressure ...

CIP (Clean-In-Place) systems are used for cleaning the equipment used in the production of beverages, beer, cider, fruit juices, foodstuffs, dairy products, pharmaceutical products, and generally in all those sectors that demand high ...

CIP (cleaning in place) systems are used for cleaning the equipment used in the production of beverages, fruit juices, foodstuffs, dairy products, pharmaceutical products, and generally in all those sectors that demand high standards ...

CIP (cleaning in place) systems are used for cleaning the equipment used in the production of beverages, fruit juices, foodstuffs, dairy products, pharmaceutical products, and generally in all those sectors that demand high standards ...

CIP - Cleaning In Place -is a process to reliably and safely clean production lines. Bucher Unipektin has been manufacturing units of various types for years. The scope of supply comprises of simple manual units as well as fully automated ...

The CIP plant provides multiple lines for cleaning of pipes, tanks and process technology in the brewery. Custom vessels setup (insulation, volume, size). Simultaneous concentrate dosing. Automatic CIP sequencing with defined temperature, ...

You want a maximum hygiene system. With our Innopro CIP cleaning system we can give you just this. Specially developed for hot and cold cleaning this machine can sanitize your entire process and filling line. Microbiological safety is ...

KHS GmbH

•Automatic washing CIP. •CIP washing systems are designed and manufactured for the sterilization and washing of all types of milk tanks and machines. •The system provides a wash with water and soda and acid solutions. •Time and temperature ...

Cleaning is an integral part of production We design automatic, personalized CIP systems. Our iAM CLEAN system may be combined with any winery system. Accurate traceability With automation, you can also track all processes and operational ...

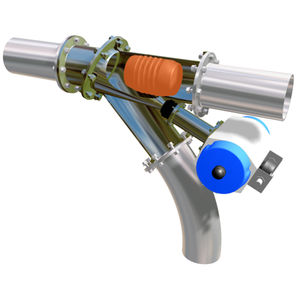

The entire pigging technology is controlled by a PLC that takes into account the detection and speed of the pig. The electro pneumatic valves are housed in a stainless-steel box. The method of pushing the pig through the transfer line ...

CIP : Closed-loop cleaning with recovery of washing solutions, for piping and closed-type equipment. Manual or automated system. Optimization of the hygiene and washing characteristics of equipment. Control of flow, temperature, ...

Our Mobile CIP: A stainless Steel Skid on wheels, compact and easy to connect with flexible hoses. Control by touchscreen, with Data History and remote control from your smartphone. Great Savings of Chemicals, Energy, Labour, and ...

CIP station is designed for sanitary cleaning of pipelines, buffer tanks, bottling lines, pasteurization plants to remove contaminants without the need of equipment disassembly. CIP station provides high performance and allows maintaining ...

CIP-stations are used for in-place cleaning of the technologic and packaging equipment in place of its usage. The stations perform preparation, warming and circulation of the cleaning solutions in product circuit of automatic machines, ...

Regular, thorough cleaning maintains the quality of your products, increase the operational life of your machines and therefore protect your investments. You will find customised cleaning systems for every application and every requirement ...

The purpose of the CIP plant is to sanitize the production plant, by means of a particular sequence which provides initial rinsing, washing by means of alkaline and acid solutions, final rinsing with water. The wash program can be carried ...

The complete solution for plants of all sizes. It has integrated tanks with chemical solutions for complete recovery and significant savings in chemicals and water usage. It is ready to operate in fully automatic mode. All the operational ...

AS AUTOMATION SYSTEM HELLAS

The CIP Station, single-piece, fully automated, permit: • Easy and quick installation for the customers. • A real progress: • In the energy saving • In the reduction of the effluent release Turnkey CIP: • Independent heating ...

The A&B Process Systems family of standard Clean-in-Place (CIP) skids is designed to fit your needs. With three flow rates and up to four tanks per flow rate, there is a total of 12 models to meet the demands of your cleaning applications. ...

Controlled cleaning and sterilization of all equipment is an essential requirement for hygienic processing of dairy products. We produce various CIP cleaning models. Starting from basic manual and semi-automatic equipment for small and ...

Production before / after-line cleaning / sanitation in the dairy industry is the only unit in the CIP does not allow making, soft drinks, carbonated drinks and ready-designed form suitable for use in the food industry. The main feature ...

The CIP350/CIP unit is a mobile unit with a compact footprint. It enables you to perform cleaning in place (CIP) of equipment, pipework and vessels without dismantling. Connecting the system to your equipment is fast and easy. For ...

Effortless, highly efficient and safe The CIP351 system is an automated CIP unit, that is designed to clean pilot plants without dismantling. Cleaning in place (CIP) is important for guaranteeing food safety in food processing plants. ...

Dion engineering offers C.I.P. modules for egg processing equipment. What is C.I.P.: Clean in place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without ...

Hygiene is such a vital factor during food processing that it should be considered as one of the production process steps. Incorrect cleaning in the food industry can lead to the loss of an entire day’s production and directly affect ...

INOXPA

Hygiene is an essential part of the processes of the food processing, cosmetics, pharmaceutical industries as a correct cleaning of all the elements is required (tanks, pipes, pumps, etc.). In addition, the last sterilization stage is ...

INOXPA

Hygiene is such a vital factor during food processing that it should be considered as one of the production process steps. Incorrect cleaning in the food industry can lead to the loss of an entire day’s production and directly affect ...

INOXPA

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining