- Food industry >

- Other Food Machinery >

- Defrosting chamber

Defrosting chambers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... product thawing chamber High capacity thawing from -20°C to -0,5°C in 3,5 hours. PERUZA Frozen fish thawing chamber reduces drip loss and water consumption. Frozen fish thawing chamber ...

... Conventional defrosting systems (still air thawing, forced air/blast thawing, water sprinkling, water immersion systems, etc..) are slow and often generate product waste due to the poor process control. Differently, ...

... Conventional defrosting systems (still air thawing, forced air/blast thawing, water sprinkling, water immersion systems, etc..) are slow and often generate product waste due to the poor process control. Differently, ...

The latest addition to the Porvair Sciences range of microplate equipment is this handy single-rack microplate thawing station. Ambient air is continuously and gently circulated across the base of the frozen microplate or tube rack, ensuring ...

Rapid defrosting equipment for fish and seafood Defrost in minutes, avoid drip loss, improve yield. Thanks to the rapid and gentle Radio Frequency tempering process, the physical, biological and nutritional integrity ...

Stalam S.p.A.

... modular thawing chamber for batch thawing of block frozen and IQF products. Defrosting is by humid air and the product retains its quality during thawing, as the Cabinplant thawing chamber ...

Faced with the general use of frozen raw ingredients in the majority of industrial food preparations, the defrosting operation has become a key phase in the food transformation process. Mastering this operation ...

... ensures low investment and flexible capacity comparing to traditional thawing systems. The chamber can be constructed welded, thus offering also mobility. The chambers are controlled via the EasyTouch ...

... the food and transfer to the interface. Therefore, surface heating managed and heat provision is optimized for a faster defrosting and optimum food quality and safety. Benefits High speed air circulation, which ...

Provisur Technologies Inc.

... detected by special probes inside the chamber as well as at the product core and surface. With this system, the defrosting process is implemented gradually without damaging the product. At the end ...

... antifreeze, or ammonia •The controlled defrosting process does not unnecessarily affect the raw material on the surface of the defrosted blocks •Controlled defrosting ensures minimal weight loss of ...

SEAFOOD DEFROSTING TANKS - FDG Tanks for defrosting seafood and other frozen products Model FDG DEFROSTING AND SETTING UP FISH TUNNEL - FDM-1200 Tunnel to defrost and prepare fish Model FDM-1200

... improved quality due to speedy defrosting period (10~30minutes) ② Thickness of food doesn't matter, the gap of temperature between inside and outside is within 3 ℃, so defrosting quality is excellent. ③ ...

Chamco

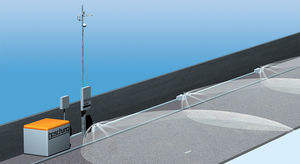

The patented MTS Mini Thawing System allows prevention and removal of black ice in winter conditions while taking ecological and economical requirements into account. It is particularly suitable for small-surface applications and is ...

... the conveyor belt and into the 4 tracks of the water bath. Defrosting process of the human plasma There, the plasma bottles move through the heated water bath while submerged. The defrosting causes ...

Your suggestions for improvement:

Receive updates on this section every two weeks.

Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining