- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

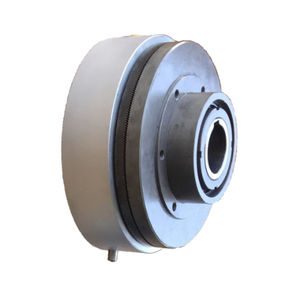

Toothed clutch ENpneumaticfor high-torque applicationsfor heavy-duty applications

Add to favorites

Compare this product

Characteristics

- Type

- toothed

- Operation

- pneumatic

- Applications

- for high-torque applications, for heavy-duty applications

- Other characteristics

- through-bore

- Torque

125 Nm, 200 Nm, 300 Nm, 500 Nm

(92.1953 ft.lb, 147.5124 ft.lb, 221.2686 ft.lb, 368.7811 ft.lb)- Rotational speed

Max.: 3,000 rpm

(18,849.56 rad.min-1)1,500 rpm

(9,424.78 rad.min-1)Min.: 0 rpm

(0 rad.min-1)

Description

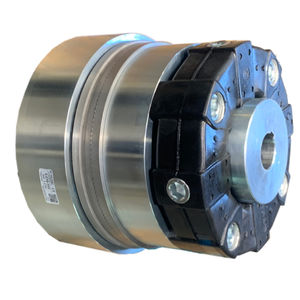

The EN Tooth Pneumatic Clutch is a compact unit that has two air inlets for its control:

The first entrance is directed towards the camera and is intended to clutch. And the second is destined to disengage.

Clutching must be done at rest or at low speed, disengagement can be done at any speed.

This Pneumatic Clutch has the same function as a double effect piston.

The cylinders of the Actuating Pneumatic Tooth Clutch EN are fed radially with compressed air at a nominal pressure of 5.5 bar.

Due to its mechanical characteristics, it allows large torques when using the Hirth teeth as a coupling means.

Depending on the tooth arrangement, the clutch can be made to be positional, that is, to maintain synchronism between the driver and the driven.

The EN Toothed Pneumatic Clutch can be used for different types of machinery such as:

Packaging Machines.

Packaging Machines.

Labeling Machines.

Printing Machines.

These are just a few examples of the machines for which the EN Tooth Pneumatic Clutch can be used.

Here we explain some of the main characteristics of the product.

Large pairs in small dimensions.

Possibility of synchronism.

Possibility of stop / start detector.

Related Searches

- Flexible shaft coupling

- Shafts coupling

- Friction brake

- Spring brake

- Disc brake

- Electromagnetic brake

- Friction clutch

- Sleeve shaft coupling

- Hydraulic brake

- Overload clutch

- Electromagnetic clutch

- Safety brake

- Misalignment correction shaft coupling

- Pneumatic brake

- Maintenance-free shaft coupling

- Spring activated brake

- Disc clutch

- Emergency brake

- Machines coupling

- Torsionally rigid shaft coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.