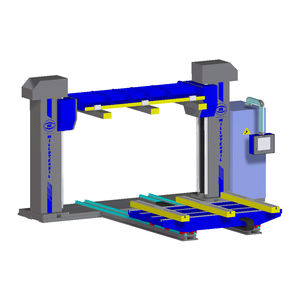

Oleodynamic press BV 26 C assemblytestdie-spotting

Add to favorites

Compare this product

Characteristics

- Operation

- oleodynamic

- Function

- assembly, test, die-spotting, tryout, fusing

- Structure

- column type, 4-column, with movable table, rotating table

- Other characteristics

- with pressure regulator

- Applications

- for industrial applications, for the automotive industry, for plastics, for automotive parts, repair

- Force

300 kN

- Table width

980 mm

(39 in)- Table length

750 mm

(30 in)

Description

Entry level-version for small and medium size moulds.

The BV 26 C is the entry level version of the Millutensil’s spotting presses.

The control panel of the BV 26 C is equipped with user-friendly graphics to simplify the use of the spotting press.

Platen dimensions are 980×750 mm (38X29 inches).

The max. clamping force is 300kN.

The max. load capacity on lower plate is 4.000 kg, while on the upper is 1.200 kg.

As all series, the BV 26 C series can also be equipped with all optional accessories.

Lower plate

Hydraulic cylinders drive the lower extensible plate outside the columns in an easily accessible position for the work outside the press.

It slides on roller bearings and is laterally guided by ball bearings, completely friction- and wear-free.

In the final position, the plate comes down and is held by 4 hydraulic cylinders, thus completely leaning on specific ground support bands. The system guarantees high repeatability accuracy equal to ± 0,04 mm.

ower plate tilting by 75° or 90°

only available on the E series

Thanks to 2 hydraulic cylinders, the lower plate can be tilted up to 75° or 90°, on the short back side, to operate on the mould at an ergonomically better position.

Tilting movements (and automatic locking) are controlled by the touch panel.

The plate can be placed at any angle, giving the operator optimal access to the mould, with no need to bend, maximum comfort and safety.

Catalogs

Die & mould spotting presses BV

28 Pages

Die & mould spotting presses MIL

40 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Industrial press

- Hydraulic press

- Automatic press

- Assembly press

- PLC-controlled press

- Four column press

- Drilling press

- Press for the automotive industry

- Press for industrial applications

- Compact press

- Plastic press

- Test press

- Automotive part press

- Riveting press

- Die-spotting press

- Press with pressure regulator

- Tryout press

- Repair press

- Oleodynamic press

- Press with movable table

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.