- Machine-tools

- Cutting Tool

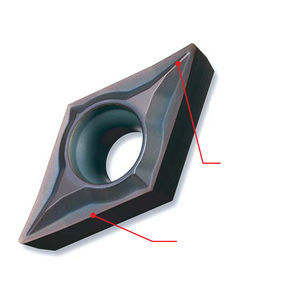

- Negative turning insert

- MITSUBISHI MATERIALS

Negative turning insert MC6025CVD coatedfor steel

Add to favorites

Compare this product

Characteristics

- Type

- negative

- Material

- CVD coated

- Other characteristics

- for steel

Description

for multi-functional turning steels

The optimum coating designed to prevent crater and flank wear means that MC6025 is a stable and versatile grade and is the first choice for general steel applications.

The latest high performance P20 grade MC6025 features 2

in 1 technology. This combines 2 types of CVD coatings that

can deliver a machining performance to fully satisfy modern production requirements. The ultra smooth top layer, a CVD nano-texture coating consists of TiCN which has been made finer and more uniform by the use of a process called crystal growth control technology. Additionally, this technology also allows a much more uniform Al2O3 layer that provides the important higher wear and fracture resistance, thus ensuring extended tool life at the high speeds required for a P20 grade.

The side faces have a Black super-even coating. This is also extremely smooth and stabilises wear development during machining due to reduced friction and helps achieve higher dimensional accuracy of the finished component. Furthermore, the reduced friction prevents abnormal damage such as weld chipping and allows stable machining over prolonged periods.

VIDEO

Catalogs

C005E

1231 Pages

Related Searches

- Milling tool

- Solid milling tool

- Steel milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Milling tool with cylindrical shank

- Metal milling tool

- Insert milling tool

- End mill milling tool

- Indexable cutting insert

- Coated milling cutter

- Cast iron milling tool

- Hemispherical milling cutter

- General purpose drill bit

- Shell-end milling tool

- Roughing milling tool

- Face milling tool

- Carbide drilling tool

- Aluminum milling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.