- Industrial machines and equipment

- Surface Treatment Equipment

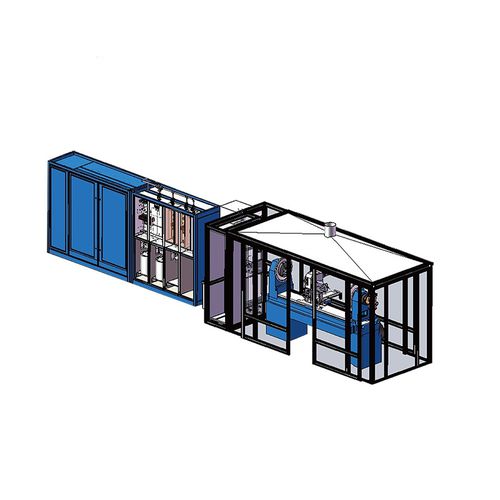

- MOCVD deposition machine

- Yangtze Optical Electronic Company Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

MOCVD deposition machine Preform Fiber Production Equipment

Add to favorites

Compare this product

Characteristics

- Method

- MOCVD

Description

MCVD is the abbreviation of Modified Chemical Vapor Deposition, which is translated as improved chemical vapor deposition. The production method of prefabricated rod was first proposed by Bell Laboratories in the United States and Southampton University in the early 1970s, and invented by Bell Laboratories in the United States in 1973.

In view of the strong flexibility of MCVD equipment in preparing different kinds of preforms, it has become one of the four main methods to produce high-quality preforms for communication optical fibers, and has a wide range of applications in the field of manufacturing special optical fiber preforms for sensing and laser.

MCVD method can deposit higher purity silicon dioxide (SiO2) on the inner wall of quartz tube (commonly called liner) with high quality (high purity, low moisture and low impurities), Other high-purity substances that can change the refractive index or vitreous viscosity, such as germanium dioxide (GeO2), phosphorus pentoxide (P2O5), silicon oxide fluoride (SiO1·5F), etc., are doped to form cores and cladding with different refractive indices, so as to achieve total reflection, low loss and high capacity when optical signals propagate in the fiber core.

Catalogs

Other Yangtze Optical Electronic Company Ltd. products

Special Optical Fiber Equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.