- Machine-tools

- Machining Center

- 3-axis machining center

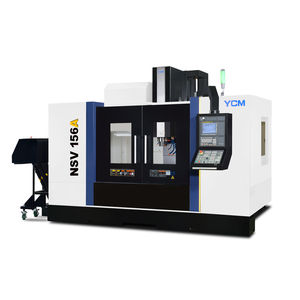

- YCM (Yeong Chin)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

3-axis CNC machining center TV2110BverticalBT 5024 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- BT 50

- Number of tool stations

- 24 tools, 40 tools, 32 outils

- Applications

- cutting, for heavy-duty machining

- Other characteristics

- high-speed, high-precision, high-rigidity, high-power, direct-drive

- X travel

2,100 mm

(83 in)- Y travel

1,020 mm

(40 in)- Z travel

762 mm

(30 in)- Rotational speed

6,000 rpm, 10,000 rpm

(37,699 rad.min-1, 62,832 rad.min-1)- Power

Min.: 15 W

(0.02 hp)Max.: 45 W

(0.06 hp)- Work feed X-axis

12,000 mm/min

(8 in/s)- Work feed Y-axis

12,000 mm/min

(8 in/s)- Work feed Z-axis

12,000 mm/min

(8 in/s)- Table load capacity

7,000 kg

(15,432 lb)- Weight

25,500 kg

(56,217.88 lb)

Description

The Best Force Flow T-base Design

The unique T-base structural design has been awarded a patent from Taiwan, China and the U.S.A. Its overhang free table movement is supported by highly rigid MEEHANITE® castings to ensure the best dynamic leveling accuracy, machining rigidity and durability.

The long travel of X-axis lies on the top of the base, where the saddle moves along the full stroke; the cross Y-axis saddle supports the work table.

The T-base rigid structure has full stroke support and do not have overhang problem guarantees the most dynamic leveling accuracy.

All axes are equipped with hardened and precision ground integrated square guideway with durable Turcite-B lubrication coating.

Sophisticated scraper work guarantees the best contact and perfect surface of the components to assure flawless accuracy.

n Sufficient support areas of all guideways give the best damping capacity and gain the best cutting rigidity.

All precise ballscrews are pre-tensioned and directly coupled with powerful servo motors to reduce backlash and ensure the best accuracy.

Inner-rail design on Z-axis ensures smooth movement of the headstock during heavy cutting performance. And the counter weight of Z-axis headstock is secured by guide bar to minimize machining vibration.

The Y-axis is equipped with 4 guideways to gain the best support and forceflow.

Catalogs

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- Precision CNC machining center

- 2-axis turning center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Turning center with turret

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.