- Machine-tools

- Machining Center

- 3-axis machining center

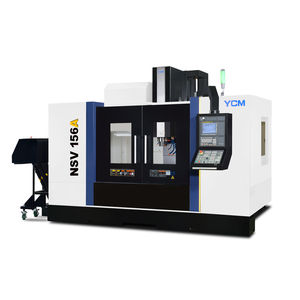

- YCM (Yeong Chin)

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

3-axis CNC machining center FV102A-APCverticalBBT4024 tools

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Spindle mount

- BBT40

- Number of tool stations

- 24 tools

- Applications

- for automatic tool changers

- Other characteristics

- high-speed, high-precision, high-rigidity, high-power, with pallet changer

- X travel

1,020 mm

(40 in)- Y travel

520 mm

(20 in)- Z travel

540 mm

(21 in)- Rotational speed

10,000 rpm, 12,000 rpm, 15,000 rpm

(62,832 rad.min-1, 75,398 rad.min-1, 94,248 rad.min-1)- Power

15 kW

(20.39 hp)- Work feed X-axis

24,000 mm/min

(16 in/s)- Work feed Y-axis

24,000 mm/min

(16 in/s)- Work feed Z-axis

24,000 mm/min

(16 in/s)- Table load capacity

400 kg

(882 lb)- Tool-changing time

1 s

- Weight

6,360 kg

(14,021.4 lb)

Description

Reliable ATC Unit

Fast and reliable roller gear cam ATC allows ATC time in 3.5 seconds, lower the idle time and enhances the machining efficiency.

The ATC units were running tested more than 72 hours before their mass production to ensure high reliability.

Complete chips disposal system

Ensure the cleanness of the machining environment. Optional flush coolant can be used to prove the chips disposal efficiently.

Screw type chip conveyor makes the chips disposal more easily & efficiently.

Complete set of the Y-axis back side plate well protects the guide-way for durable operation.

APC's swivel arm is driven by X-axis servo motor with unique rack transmission design, features fast and accurate pallet change mechanism.

APC time is around 15 seconds.

Oversized taper pins are applied to ensure backlash-free positioning and rigid clamping on the pallet.

APC feed rate is adjustable to appropriate speed for different workpieces' demand.

Tough and durable MEEHANITE castings deliver exceptional cutting stability and consistent accuracy - the massive, rigid internally ribbed construction reduces damping effect for superb part finishing.

The extra wide column base and machine base maximize the cutting rigidity, and enhance machine stability during heavy-duty machining.

Catalogs

No catalogs are available for this product.

See all of YCM (Yeong Chin)‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- CNC machining center

- Vertical CNC machining center

- Turning center

- 3-axis CNC machining center

- CNC turning center

- Precision CNC machining center

- 2-axis turning center

- 5-axis CNC machining center

- High-precision CNC machining center

- Rigid CNC machining center

- High-performance CNC machining center

- High-precision turning center

- Gantry CNC machining center

- High-rigidity CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Column type CNC machining center

- High-productivity CNC machining center

- Aluminum CNC machining center

- Turning center with turret

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.