- Metrology - Laboratory

- Metrology and Test Equipment

- Straightness measuring system

- ZUMBACH Electronic AG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Straightness measuring system BENDCHECKlaserreal-timetube

Add to favorites

Compare this product

Characteristics

- Measured physical value

- straightness

- Technology

- laser, real-time

- Measured material

- tube

- Applications

- for production lines

- Other characteristics

- non-contact, in-line, rugged

Description

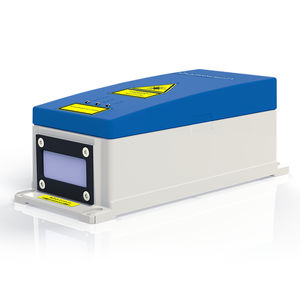

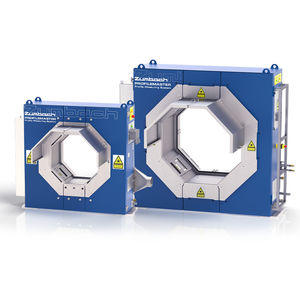

In-line laser measuring device for measuring straightness on rods and tubes

Properties

Synchronous real-time scan to monitor bending of the product

3 to 5 non-contact measuring stations with 1 to 3 measuring axes

Direct integration into the existing production process

Constant quality assurance, also after the straightening process

Recording of statistics, ensuring traceability

Time savings thanks to automatic measurement control

Continuous measurement without slowing down the production process

Replaces manual measurements by means of off-line stations

Optional measurement of head and tail bending with additional measuring stations

Benefits

• Cutting-edge optics and laser scan technology

• Maximum accuracy and stability

• Extremely high sampling rate

• Comprehensive quality control

• Permanently calibrated

• Extremely dirt resistant

• Robust and durable design

Areas of application

The BENDCHECK system is suitable for in-line production optimization in the steel and metal industry.

The measuring solution enables in-line quality assurance in the production of tubes and rods and eliminates the need for complex manual straightness measurements.

Catalogs

BENDCHECK

4 Pages

ZUMBACH Electronic AG - General

32 Pages

Related Searches

- Measuring device

- ZUMBACH measuring system

- Cabling tester

- Insulation tester

- Automatic measuring machine

- ZUMBACH high-precision measuring system

- Automatic measuring device

- Measuring system for industrial applications

- Parts measuring machine

- Compact testing system

- Geometry measuring device

- ZUMBACH laser measuring system

- Rugged testing system

- ZUMBACH non-contact measuring system

- ZUMBACH diameter measuring system

- Compact measuring machine

- Thickness measurement system

- Dimensional measuring machine

- Laboratory measuring machine

- High-speed measuring machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.